OSHA inspections don’t come with a warning. One day, your records might seem like nothing more than stacks of paperwork—until the moment an inspector asks to see them. Suddenly, they become your first line of defense, the difference between a routine check and costly penalties.

If those files are incomplete or disorganized, even the safest workplace can land in serious trouble.

Having proper documentation isn’t about paperwork for the sake of paperwork. It’s about proving that safety measures are in place and actively followed.

OSHA’s 29 CFR 1910.134 explicitly requires businesses to maintain records on respiratory protection programs, fit tests, employee training, and air quality assessments. Without these, even a well-run operation can find itself in trouble.

Instead of scrambling at the last minute, businesses that keep accurate, up-to-date records always have the upper hand.

Knowing what OSHA requires, how to keep accurate records, and where to store them can make audits easier. This can help avoid compliance problems.

I. Types of Documents Reviewed During an OSHA Audit

Ensuring your documentation is complete and accurate is essential for passing an OSHA audit. The table below outlines key documents inspectors typically review, their purposes, and what they should contain.

| Document Type | Purpose | Key Components | OSHA References |

|---|---|---|---|

| Respiratory Protection Plan (RPP) | Outlines procedures to protect employees from respiratory hazards. | – Written policies for respirator use – Hazard assessments and selection criteria – Medical evaluation process – Fit testing procedures – Employee training requirements – Maintenance and care of respirators | OSHA Respiratory Protection Standard |

| Medical Evaluations & Fit Testing Records | Ensure employees are medically fit and properly fitted for respirator use. | – Medical clearance documentation – Individual employee fit test results (initial and annual) – Records of fit test methods used (qualitative or quantitative) – Any re-evaluation records due to changes in health conditions | OSHA Fit Testing Procedures |

| Training Logs and Certification Records of OSHA | Verify that employees have received required safety training. | – List of employees trained – Dates of training sessions – Training topics covered (e.g., PPE use, emergency procedures, respiratory safety) – Trainer credentials and qualifications – Employee acknowledgment signatures | OSHA Training Requirements |

| Workplace Exposure Assessments | Document evaluations of potential airborne hazards. | – Air quality test results (dust, fumes, gases, vapors) – Frequency and method of testing – Identified workplace hazards and exposure levels – Reports from industrial hygienists or safety personnel | OSHA Air Contaminants Standard |

| Inspection & Maintenance Logs | Track the upkeep of safety equipment to ensure functionality. | – Regular inspection reports for respirators and PPE – Maintenance schedules and completed work records – Names of inspectors/technicians performing checks | OSHA Maintenance Requirements |

| OSHA 300 Log & Incident Reports | Record work-related injuries and illnesses. | – OSHA 300 Log (summary of workplace injuries/illnesses) – OSHA 301 Forms (incident reports with detailed case descriptions) – Dates, locations, and nature of injuries – Corrective measures implemented after incidents | OSHA Recordkeeping Forms |

| Safety Corrective Action Forms | Detail responses to identified safety violations or hazards. | – Description of identified hazard or violation – Steps taken to correct the issue – Date corrective actions were completed – Person(s) responsible for implementation – Follow-up inspections to confirm resolution | OSHA Enforcement Policies |

II. Accuracy and Completeness

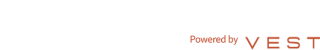

Ensuring that your OSHA documentation is accurate and complete is not just a regulatory obligation but a cornerstone of workplace safety and operational efficiency. Inaccurate records can lead to severe penalties, legal liabilities, and compromised employee safety. To help you maintain impeccable records, we’ve compiled a checklist addressing key elements and common pitfalls in OSHA documentation.

Maintain Up-to-Date and Error-Free Records

- Ensure all employee names, job titles, and details are correctly spelled.

- Record the exact dates of training sessions, inspections, and corrective actions.

- Maintain attendance logs with employee signatures for all safety training.

- Verify that training documentation matches OSHA requirements.

- Store certification records for required safety and health programs.

Action Item: Implement a regular schedule to review and update all records, correcting any inaccuracies promptly.

Ensure Consistency Between Records and On-Site Practices

- Written policies should accurately reflect actual safety procedures in the workplace.

- Regularly audit training logs to confirm employees receive the required instruction.

- Align hazard assessments with current workplace conditions.

- Verify that safety equipment maintenance logs match inspection findings.

- Ensure all corrective actions documented were fully implemented.

Action Item: Establish a cross-functional team to perform periodic reviews of both documentation and workplace practices.

Align Documents with Industry-Specific Standards

- Ensure records comply with OSHA 29 CFR 1910.134 for respiratory protection.

- Adapt documentation to meet sector-specific safety regulations (e.g., manufacturing, construction, healthcare).

- Keep records of workplace-specific hazard assessments.

- Cross-check company policies with updated OSHA enforcement guidelines.

- Maintain specialized equipment testing and inspection records.

Action Item: Assign a compliance officer to monitor changes in industry standards and update documents accordingly.

Avoid Common Documentation Mistakes

- Missing or outdated annual fit test records for respirators.

- Inconsistent training logs or attendance sheets.

- Expired or incomplete air monitoring reports.

- Missing details in workplace incident reports (OSHA form 300 logs).

- Discrepancies between documented procedures and actual safety practices.

Action Item: Implement a checklist to verify the completion and accuracy of all required records.

Utilize Digital Compliance Tools

- Store all safety records in a centralized digital system.

- Automate expiration alerts for training, fit tests, and equipment maintenance.

- Limit access to ensure only authorized personnel update compliance records.

- Keep digital backups of all OSHA-required documents.

- Ensure digital logs can be retrieved instantly during an audit.

Action Item: Invest in a reliable compliance management system and train staff on its effective use.

Conduct Regular Internal Reviews & Training

- Schedule quarterly audits to verify OSHA documentation accuracy.

- Train employees responsible for compliance with record-keeping best practices.

- Assign dedicated personnel to manage document updates.

- Review incident reports to identify trends and improve safety protocols.

- Ensure every audit or review results in actionable updates to records.

Action Item: Develop a continuous improvement plan that includes training sessions and regular audits of documentation practices.

III. Best Practices for Easy Access & Organization

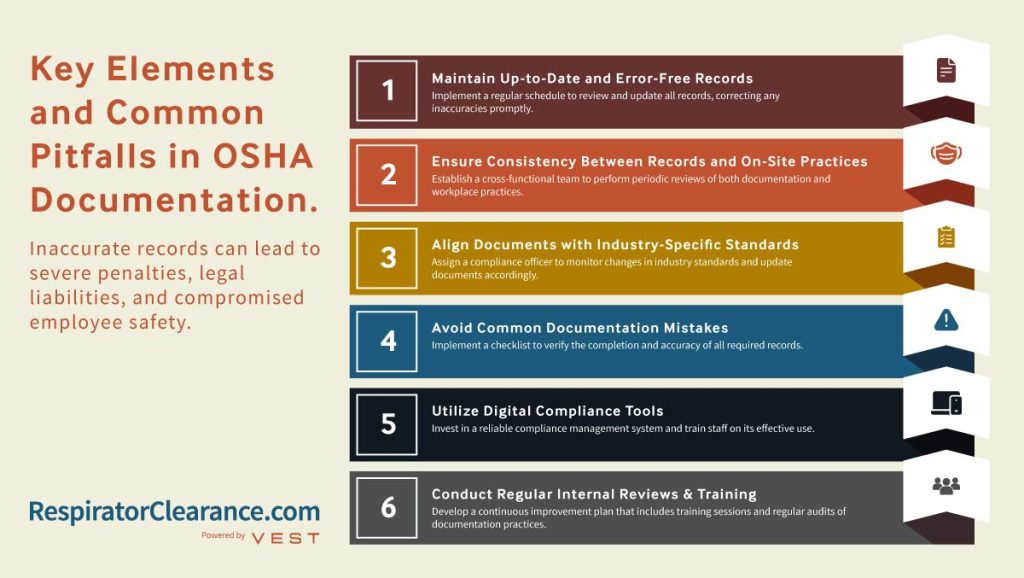

When an OSHA inspector arrives, the last thing you want is to fumble through stacks of paperwork or dig through disorganized files. Readily available and well-organized documentation demonstrates compliance and builds confidence in your workplace safety efforts.

Businesses can make the audit process smooth and easy. They can do this by using organized storage and smart management strategies.

Maintain Readily Available Records

OSHA inspectors expect quick access to essential documents, and delays can raise concerns about compliance. If records are scattered across different locations or locked in outdated filing systems, it signals poor documentation practices.

Having all necessary paperwork in one place ensures your audit runs smoothly without unnecessary roadblocks.

A best practice is to centralize records in a structured system, whether physical or digital. Create an OSHA-specific filing system where every document–such as training logs, incident reports, and equipment maintenance records–is organized by category and date.

Regular reviews of these records will help keep them updated and ensure everything is audit-ready at all times.

Digital vs. Paper Filing: Which Method is OSHA-Friendly?

Both digital and paper filing methods have their benefits, but digital storage is increasingly becoming the preferred option for OSHA compliance. Digital records offer faster retrieval, real-time updates, and better security, making audits much more manageable.

Cloud-based platforms like Google Drive, Dropbox, or specialized compliance software allow businesses to maintain searchable, easily accessible records that can be retrieved instantly when needed.

That said, paper records are still widely used, and some companies prefer keeping hard copies for backup. If using a paper-based system, it’s essential to have a structured filing cabinet with labeled folders, ensuring all documents remain secure and damage-free.

Whichever method is chosen, consistency is key–documents should be systematically filed, regularly updated, and readily available at all times.

Designate a Safety Officer for Documentation Management

Without a clear point of responsibility, documentation can quickly fall through the cracks. Assigning a dedicated safety officer to oversee compliance records ensures that everything remains organized and up to date.

This person should thoroughly understand OSHA requirements, industry-specific regulations, and company policies to ensure all documentation aligns with compliance standards.

A safety officer’s responsibilities should include routine documentation reviews, updating records as regulations change, and ensuring that all documents are stored securely. By having a single person or team in charge, businesses eliminate confusion, streamline audit preparation, and ensure their documentation is always in top shape.

Conduct Pre-Audit Internal Reviews

The best way to avoid surprises during an OSHA audit is to conduct regular internal reviews of all compliance-related documents. These internal audits act as test runs, allowing businesses to identify missing records, correct inconsistencies, and ensure all required documents are available and accurate before an official inspection.

Setting up a quarterly or bi-annual internal review schedule helps maintain compliance throughout the year. During these reviews, businesses should verify that training records are complete, incident reports are properly logged, and maintenance logs are up to date.

This proactive approach reduces the risk of last-minute scrambling and ensures that all necessary records are in perfect order when OSHA arrives.

Utilize a Central Compliance Dashboard

A centralized compliance dashboard simplifies OSHA documentation management by consolidating all required records into one easy-to-access platform. Tools like Google Drive, Dropbox, and OSHA-specific compliance software allow businesses to track training records, log inspections, and maintain an organized database of critical safety documents.

These dashboards offer features such as automatic reminders for document updates, real-time access control for authorized personnel, and enhanced search capabilities. Instead of sifting through piles of paperwork, businesses can instantly retrieve any document needed for an audit.

Investing in a structured digital compliance system ensures that OSHA documentation is always organized, up-to-date, and readily available.

IV. Compliance Verification

OSHA compliance isn’t just about having the right documents but ensuring they’re accurate, up-to-date, and ready for inspection at any moment. Following a structured process will help your business stay compliant, prevent penalties, and improve workplace safety. Let’s walk through the five-step compliance verification process.

Step 1: Conduct an Internal Compliance Audit

Routine internal audits help catch missing, outdated, or incorrect records before an OSHA inspection. Identifying gaps early allows businesses to correct issues before they turn into violations.

How to do it:

- Create an audit checklist based on OSHA’s required documentation (respiratory safety, medical records, training records, and safety logs).

- Assign a compliance team to review each document for accuracy and completeness.

- Verify that records are up to date and properly maintained according to regulatory timelines.

- Look for missing signatures, incorrect dates, or incomplete reports.

- Conduct random spot-checks to ensure on-site practices align with written documentation.

- Document all findings and establish a corrective action plan for missing or incorrect records.

Pro Tip: Keep track of past audits and log the corrections made to demonstrate continuous improvement.

Step 2: Compare Your Documents Against OSHA Standards (29 CFR 1910.134)

OSHA regulations evolve over time, and what was compliant last year may no longer meet current standards. Regularly comparing your records to OSHA’s official respiratory protection standard ensures full compliance.

How to do it:

- Download the latest version of OSHA’s 29 CFR 1910.134.

- Cross-check each section of your respiratory protection program with OSHA’s specific requirements.

- Ensure fit testing, air monitoring, and employee training logs match OSHA’s expectations.

- Verify medical evaluation records for employees using respirators.

- Update any outdated policies or training materials that don’t align with OSHA’s current standards.

- Schedule annual policy reviews to stay compliant with evolving regulations.

Pro Tip: Subscribe to OSHA’s newsletter to get notified about any new regulatory updates.

Step 3: Bring in a Third-Party Safety Consultant for an External Audit

Even the most thorough internal audits can miss compliance gaps. A third-party OSHA safety consultant offers an objective review of your safety documentation, helping you catch errors before an official audit.

How to do it:

- Hire a certified OSHA compliance consultant to conduct a full external audit.

- Provide access to all relevant documents, including training records, incident reports, and respiratory protection plans.

- Request a detailed report outlining errors, missing records, or inconsistencies.

- Implement recommended fixes and document the corrective actions taken.

- Use the consultant’s findings to improve internal processes and ensure long-term compliance.

- Schedule regular third-party reviews (e.g., annually or bi-annually) to maintain an unbiased compliance check.

Pro Tip: Keeping a record of consultant audits and fixes shows OSHA inspectors that your company actively works on improving safety.

Step 4: Train Employees on Proper Documentation Management

Even the most well-organized system fails if employees don’t understand how to update and maintain records correctly. Training prevents misfiled, lost, or inaccurate records that could cause compliance issues.

How to do it:

- Conduct annual training on OSHA’s documentation requirements and best practices.

- Develop step-by-step guides on how to maintain compliance records properly.

- Assign specific responsibilities to employees handling safety documentation.

- Provide hands-on workshops where employees practice updating training logs and medical evaluations.

- Regularly review and update documentation procedures based on employee feedback.

- Implement a verification system where a second employee cross-checks all submitted records for accuracy.

Pro Tip: Keep a training log to document who attended, what was covered, and when they last received compliance training.

Step 5: Prepare for OSHA Spot Checks & Unannounced Inspections

OSHA inspections can happen without notice, and missing documentation is one of the top reasons for citations. Being prepared year-round ensures your business doesn’t get caught off guard.

How to do it:

- Organize all required OSHA documents in an easily accessible system (either digital or physical).

- Designate a compliance officer responsible for handling OSHA inspections.

- Train staff on where to find key records in case an inspector requests them.

- Create an OSHA pre-inspection checklist to verify all documents are up to date.

- Perform random internal audits to simulate a surprise OSHA inspection.

- Ensure all safety violations and corrective actions are properly documented and resolved before inspections.

Pro Tip: Always have a “Compliance Binder” or a Digital Compliance Dashboard where all OSHA-required records are instantly available.

Watch Out for These Red Flags That Trigger OSHA Investigations

- Missing or outdated training records – OSHA expects proof that employees received proper safety training.

- Inconsistent documentation – Mismatched dates on fit test logs, training records, or maintenance reports are a red flag.

- Failure to produce records on demand – If an inspector asks for a document and it takes too long to find, it signals poor record-keeping.

Pro Tip: Conduct quarterly documentation reviews to avoid these compliance pitfalls.

V. Continuous Improvement

Staying compliant with OSHA is not a one-time task—it requires ongoing effort and regular updates to ensure that records remain accurate, accessible, and audit-ready.

A proactive documentation strategy helps businesses avoid last-minute scrambles, prevent regulatory issues, and create a safer work environment.

One of the best ways to maintain compliance is by conducting regular document reviews. Instead of waiting until an OSHA inspection is announced, businesses should schedule monthly internal audits to check for incomplete, outdated, or missing records.

This practice ensures that everything is in order before an inspector ever sets foot in the workplace.

Beyond catching mistakes, frequent reviews reinforce accountability. When employees know their records will be checked consistently, they are more likely to keep documentation updated and accurate. Additionally, having a structured OSHA audit checklist makes tracking which documents require attention easier, helping businesses stay organized year-round.

Next, while routine reviews help identify issues, someone needs to be responsible for fixing them. Assigning a dedicated compliance officer or team ensures that documentation is consistently managed and maintained.

These personnel act as the go-to experts for regulatory updates, training coordination, and document accuracy.

Having a transparent chain of responsibility prevents lapses in compliance. Organizations can rely on pre-designated staff to handle record-keeping efficiently instead of scrambling to assign tasks when an issue arises.

Over time, this structured approach helps reduce errors, maintain consistency, and improve overall compliance readiness.

Moving forward, manually tracking compliance records leaves room for human error. That’s why many businesses turn to automated compliance tracking software to help manage OSHA documentation.

These tools can flag missing records, send reminders for expiring certifications, and organize safety logs in a centralized database.

Using cloud-based platforms allows businesses instant access to OSHA-required documents whenever needed. This saves time during audits and provides real-time compliance monitoring, reducing the risk of outdated or incorrect records slipping through the cracks.

Moreover, even the best compliance system is only as effective as the people managing it. If employees aren’t adequately trained on OSHA documentation requirements, mistakes will happen—no matter how organized the system is.

Organizations should hold annual training sessions focused on record-keeping best practices, OSHA updates, and document retrieval procedures to avoid these issues.

Additionally, periodic refresher courses ensure that employees stay up to date with the latest compliance expectations.

By reinforcing training regularly, businesses create a workforce that understands the importance of documentation accuracy, reducing the risk of non-compliance due to human oversight.

Lastly, OSHA (Occupational Safety and Health Administration) regulations can change over time; static policies quickly become outdated. To stay compliant, businesses must regularly update their documentation procedures to reflect new regulations, industry standards, and best practices.

A good practice is to review company policies every six months and cross-check them against the latest OSHA guidelines. Updates should be communicated to all relevant employees if changes are needed, and new training sessions should be scheduled if necessary.

This ensures that compliance efforts remain proactive rather than reactive, helping businesses avoid unnecessary fines or penalties.

Staying OSHA-compliant requires accurate documentation, easy accessibility, and ongoing verification. Regular internal audits help businesses identify gaps, correct errors, and stay prepared for inspections. A proactive approach reduces risks, prevents penalties, and ensures workplace safety remains a top priority.

Why Choose RespiratorClearance for OSHA Compliance?

Compliance can be overwhelming, but Respirator Clearance simplifies the process. From respirator medical evaluations to documentation support, we help businesses easily meet OSHA standards.

Stay audit-ready, avoid fines, and protect your workforce. Contact RespiratorClearance today to ensure your compliance is always in check!

For more information or a consultation, just visit our website.