Did you know? An OSHA violation can cost up to $16,131, but if deemed willful or repeated, that figure would skyrocket up to $161,323 per violation. But before fines are set in stone, there’s one last opportunity to take control: the closing conference.

This is when OSHA inspectors present their findings, outline potential citations, and decide whether your company faces costly penalties or walks away with a clean slate.

To cut the long story short, it’s a moment that isn’t just procedural; it’s where compliance, finances, and reputation are on the line.

The closing conference isn’t just a debriefing. It’s an opportunity to push back on inaccuracies, demand clarity, and take control of the next steps before citations become final.

Understanding the inspection process can mean the difference between crippling penalties and a manageable compliance strategy. Employers who come prepared can correct errors, mitigate fines, and protect their workforce–but only if they know how to handle this conversation effectively.

So, what should you expect in this final phase? From dissecting citations to negotiating corrective actions, the closing conference isn’t a formality–it’s a defining moment for your company’s compliance standing.

Learn how to take charge so you leave with a plan and not a financial setback.

I. Review Preliminary Findings

Once the OSHA inspection progresses to the OSHA closing conference, the first order of business is reviewing the preliminary findings. This is when inspectors outline their observations, highlighting potential violations and compliance concerns.

It’s not just a formality but your last chance to correct inaccuracies, provide clarifications, and ensure that every issue is properly documented before citations are finalized.

Understanding the Compliance Officer’s Report

The OSHA compliance officer will present a detailed account of the inspection checklist, covering workplace hazards, procedural missteps, and regulatory violations. This report isn’t a final verdict, but it does set the stage for potential citations.

Each finding will connect to an OSHA (Occupational Safety and Health Administration) standard. This helps employers see where they need to improve compliance.

Some violations are straightforward–like missing safety signage or inadequate personal protective equipment (PPE). Others are more technical, involving air quality levels, machine guarding requirements, or recordkeeping discrepancies.

Employers should listen carefully and take notes, ensuring they understand each concern before responding. Misinterpreting findings or failing to ask for clarifications could mean accepting violations that aren’t accurate.

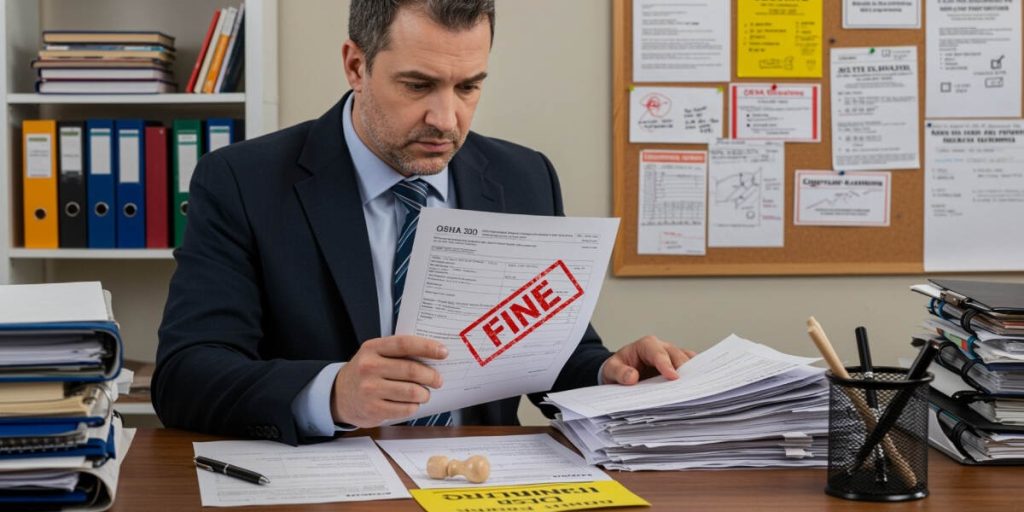

How to Review and Verify Findings

OSHA’s preliminary findings are subject to review, clarification, and even correction. Before accepting any violations, employers should take a methodical approach to ensure the findings are accurate, evidence-based, and justified.

Use this step-by-step process to analyze and challenge findings where necessary.

Step 1: Cross-Check OSHA’s Findings with Internal Records

Before responding to OSHA’s preliminary report, take the time to compare their observations with your internal safety logs, training records, and maintenance reports.

Sometimes, findings are based on assumptions rather than actual regulatory violations, especially if documentation was not reviewed thoroughly during the OSHA audit.

What to Do:

- Gather incident reports, compliance logs, and recent safety inspections related to the identified issues.

- Verify whether the cited hazards were already addressed before the inspection took place.

- Identify any discrepancies between OSHA’s report and your actual workplace conditions.

Example: If OSHA claims that employees were not provided with respiratory protection, pull out your fit-test records and PPE distribution logs to confirm whether this is accurate. If it’s incorrect, flag this finding for discussion.

Step 2: Request Clarifications & Ask for Supporting Evidence

Not every violation is as clear-cut as it seems. If a compliance officer reports a hazard without referencing specific OSHA regulations, ask for clarification before accepting the finding.

Inspectors are required to provide the legal basis for each citation, and employers have every right to challenge vague or incomplete assessments.

What to Ask the Inspector:

- Which OSHA standard is this finding based on?

- What specific evidence supports this violation?

- Were all relevant records reviewed before making this determination?

How to Handle This Step:

- If a violation seems broad or subjective, ask for OSHA’s official documentation related to the standard.

- If needed, request additional time to gather and present your own compliance evidence.

Example: If an inspector cites air quality concerns but hasn’t reviewed your latest monitoring reports, politely request that they assess this data before finalizing their findings.

Step 3: Present Additional Documentation or Evidence

If OSHA’s findings miss key details, proactively provide records that contradict or clarify the citation. Compliance officers work with the information available at the time of the inspection, but they may not have seen your full documentation.

What to Submit:

- Training certifications proving that employees received the required safety instruction.

- Equipment maintenance logs showing that cited hazards had already been addressed.

- Internal audit reports that prove ongoing compliance efforts.

How to Present This:

- Bring clear, organized copies of relevant records to the discussion.

- Politely request that the compliance officer re-evaluate the finding based on this new information.

Example: If you’re cited for not having an emergency eyewash station, but your installation records show it was put in place before the audit, submit that proof and ask the inspector to amend the report.

Step 4: Address Discrepancies & Request Adjustments

At this point, you should have identified whether OSHA’s findings are accurate, partially correct, or completely incorrect. If discrepancies exist, it’s time to discuss corrections before the final report is issued.

What to Do:

- Politely challenge any inaccurate findings and ask if they can be adjusted.

- If a citation is valid but mitigating factors were not considered, present your case for why the penalty should be reduced.

- Document any verbal agreements or clarifications made during this discussion.

Example: If OSHA reports that forklift operators weren’t properly trained, but you provide certifications proving otherwise, request that this finding be revised or removed before the final citation list is issued.

Step 5: Confirm the Final Version of the Findings

Once you have reviewed, clarified, and disputed any questionable findings, request a final summary of the report before the closing conference concludes.

What to Ensure Before Accepting the Report:

- Any withdrawn or corrected findings are acknowledged in writing.

- Final findings align with actual workplace conditions and OSHA’s regulatory framework.

- You have a clear understanding of the next steps, including timelines for corrective actions or contesting citations.

Example: If an inspector agrees to remove or revise a citation, ensure that this is documented in the official findings before the closing conference ends.

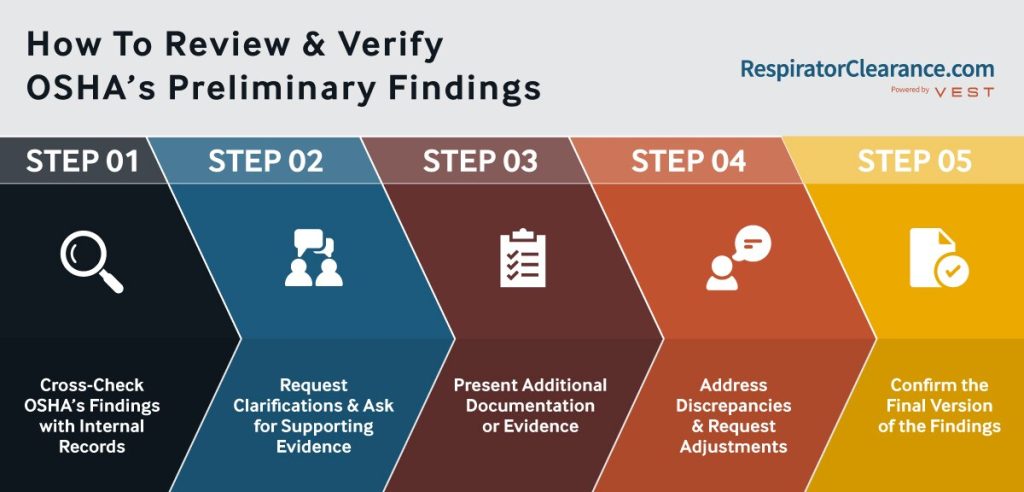

Avoiding Common Mistakes & Misunderstandings

Miscommunications during this stage can lead to unnecessary citations, costly penalties, and operational disruptions. Many employers assume that OSHA’s findings are set in stone, but this phase is an opportunity to correct errors, present missing information, and clarify misunderstandings before citations are finalized.

- Not Asking for Clarifications – Some citations are based on broad observations rather than specific violations. Always request the exact OSHA regulation and supporting evidence before accepting a finding.

- Failing to Document the Discussion – If an inspector verbally agrees to modify or remove a citation, ensure it’s recorded in writing. Without documentation, changes discussed may not be reflected in the final report.

- Overlooking Minor Issues – Small violations, like unlabeled chemicals or blocked emergency exits, can still result in citations. Addressing these issues before the audit concludes helps prevent unnecessary penalties.

- Assuming Immediate Fixes Will Remove Citations – Correcting a violation on the spot doesn’t always mean OSHA will dismiss it. Always ask whether the correction affects the final report or if the citation will remain.

- Not Assigning a Point of Contact for Follow-Ups – If OSHA requires additional information, delays in response can create complications. Assigning a safety manager ensures timely follow-ups and compliance verification.

II. Explain Citations and Penalties

When OSHA issues citations, they aren’t all the same. Some carry steep financial penalties, while others signal repeat violations that can escalate enforcement actions. Understanding these distinctions is critical for employers who need to assess risks, challenge inaccuracies, and take corrective action before fines add up. Below are the top 10 frequent citations with company samples.

| Type | Citation | Number of Violations | Example of Company Cited |

|---|---|---|---|

| Fall Protection—General Requirements | 1926.501 | 7,271 | Vance Brothers Construction, Inc. |

| Hazard Communication | 1910.1200 | 3,213 | Williams Olefins, Llc. |

| Ladders | 1926.1053 | 2,978 | Primetime Contractors Llc |

| Scaffolding | 1926.451 | 2,859 | Everest Scaffolding Inc. |

| Powered Industrial Trucks | 1910.178 | 2,561 | Central Transport Llc. |

| Lockout/Tagout | 1910.147 | 2,554 | Walker Midwest Llc |

| Respiratory Protection | 1910.134 | 2,481 | Outdoor Furniture Refinishing, Inc. |

| Fall Protection—Training Requirements | 1926.503 | 2,112 | Hughes Brothers Construction, Inc. |

| Personal Protective & Lifesaving Equipment (Eye & Face Protection) | 1926.102 | 2,074 | Hbd Thermoid, Inc. |

| Machine Guarding | 1910.212 | 1,644 | Amazon Cmh4 |

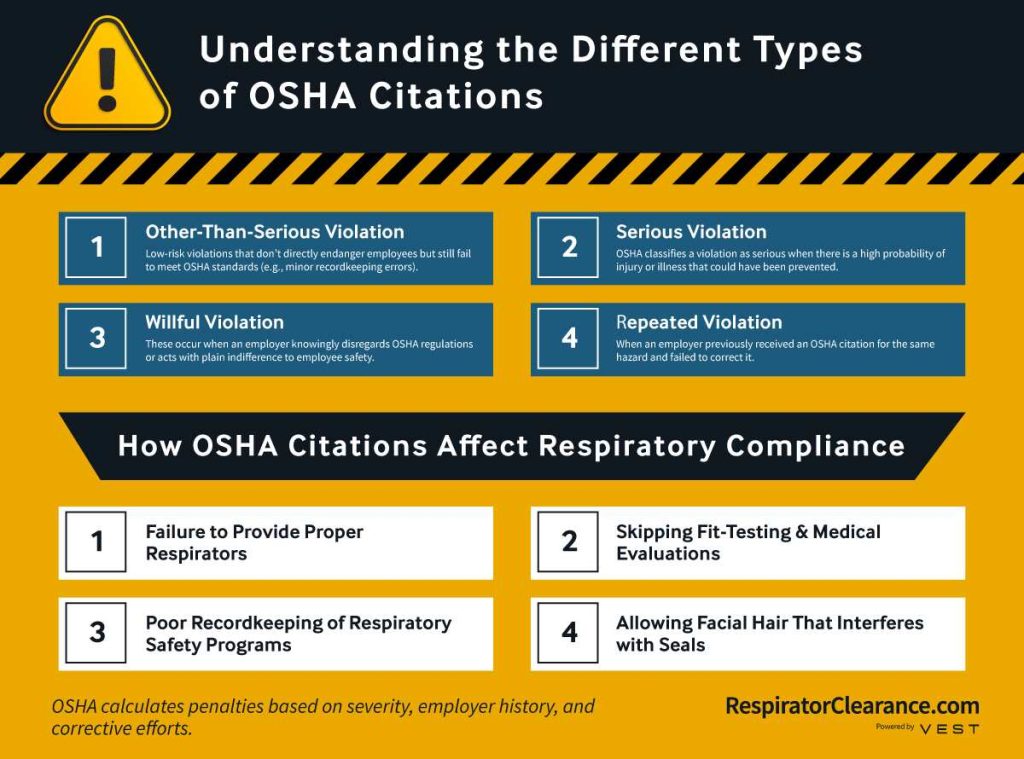

Understanding the Different Types of OSHA Citations

Not all OSHA citations hold the same weight—some point out fixable concerns, while others indicate serious risks to worker safety. Knowing the four primary categories will help employers gauge the severity of each violation.

- Other-Than-Serious Violation – These are low-risk violations that don’t directly endanger employees but still fail to meet OSHA standards (e.g., minor recordkeeping errors). Fines can go up to $16,131 per violation, but may be reduced or waived based on the employer’s history and cooperation.

- Serious Violation – OSHA classifies a violation as serious when there is a high probability of injury or illness that could have been prevented. Employers can face fines of up to $16,131 per violation, depending on the level of negligence and the impact on worker safety.

- Willful Violation – These occur when an employer knowingly disregards OSHA regulations or acts with plain indifference to employee safety. Penalties are significantly higher, with fines up to $161,323 per violation, and can result in criminal charges if worker fatalities are involved.

- Repeated Violation – If an employer previously received an OSHA citation for the same hazard and failed to correct it, it is classified as a repeat violation. These come with substantial financial penalties, reaching up to $161,323 per occurrence.

Breaking Down OSHA’s Penalty Structure

OSHA calculates penalties based on severity, employer history, and corrective efforts. Here’s how fines are structured:

- Per-Violation Fines – Every citation carries a base penalty amount, with the most severe violations reaching six figures.

- Daily Penalties for Uncorrected Violations – If employers fail to fix a cited hazard within the given timeframe, they may face additional daily fines of up to $16,131 per day.

- Good-Faith Reductions – OSHA may lower penalties for small businesses or companies that demonstrate immediate corrective action and a strong commitment to safety.

Employers’ Rights: Asking for Clarification on Citations

Employers don’t have to accept citations at face value. They have the right to request further clarification and challenge any unfair or excessive findings.

- Request the Exact OSHA Standard Referenced – Inspectors must cite the specific regulation violated and provide clear justification.

- Ask for Documentation of Evidence – Employers should review supporting documents, photos, and test results used to support the citation.

- Challenge Inconsistencies – Employers can present proof and request a revision if a cited hazard was already corrected before the audit.

- Negotiate Fine Adjustments – OSHA sometimes reduces penalties if employers show proactive safety efforts or a strong compliance history.

How OSHA Citations Affect Respiratory Compliance

Respiratory protection violations are one of the most frequently cited OSHA infractions, especially in industries involving hazardous airborne contaminants. Here’s how they fit into OSHA’s penalty system:

- Failure to Provide Proper Respirators – Employers must ensure that respirators meet NIOSH certification standards and are suitable for workplace hazards.

- Skipping Fit-Testing and Medical Evaluations – Workers required to wear respirators must undergo fit testing and medical evaluations to confirm they can safely use them.

- Poor Recordkeeping of Respiratory Safety Programs – OSHA mandates detailed written respiratory protection programs outlining procedures, training, and testing.

- Allowing Facial Hair That Interferes with Seals – Employees using tight-fitting respirators must maintain a clean-shaven face to ensure a proper fit.

III.Discuss Corrective Actions

Receiving an OSHA citation isn’t the end of the road. It’s an opportunity to fix workplace hazards, strengthen safety protocols, and prevent future violations. Employers must act quickly to meet OSHA’s requirements, document corrective measures, and prepare for potential follow-up inspections.

First, you need to meet OSHA’s Abatement Deadlines. Once a citation is issued, OSHA assigns a specific timeframe, known as the abatement period, for correcting violations. This deadline varies based on the severity of the hazard and the complexity of the corrective action.

a. Employers must take immediate steps to correct hazards that pose a direct risk to employees.

b. If more time is needed, businesses can request an extension by showing proof of progress toward compliance.

c. Failing to meet the abatement deadline can lead to additional penalties, increased scrutiny, and potential legal action.

Next, you must develop a Corrective Action Plan. A structured approach helps ensure violations are addressed thoroughly and effectively. A corrective action plan should outline clear steps, assign responsibilities, and set deadlines to prevent similar issues in the future.

a. Identify the Root Cause – Determine why the violation occurred and what led to noncompliance.

b. Assign Responsibility – Designate a safety officer or compliance manager to oversee implementation.

c. Set Clear Deadlines – Break corrective actions into manageable steps with target completion dates.

d. Train Employees – If violations involve workplace procedures or PPE, conduct additional training.

e. Prevent Recurrence – Introduce new controls or policies to maintain long-term compliance.

Then, document and report corrections to OSHA. Once hazards are corrected, employers must submit proof of abatement to OSHA. This documentation verifies that compliance has been achieved and prevents further penalties.

a. Photographic Evidence – Take before-and-after photos to visually confirm corrections.

b. Repair & Maintenance Logs – Document any fixes made to equipment or facilities.

c. Employee Training Records – Provide proof of additional training sessions for workers.

d. Official Abatement Certification – Submit OSHA’s required abatement form (OSHA 3000) confirming the issue has been resolved.

Additionally, prepare for an OSHA follow-up inspection. OSHA may return to verify that violations have been corrected. Follow-up inspections are especially likely for serious, repeat, or willful violations.

a. Keep Compliance Records Ready – Ensure all abatement documentation is easily accessible.

b. Conduct an Internal Audit – Re-inspect the workplace before OSHA’s return visit to catch any lingering issues.

c. Ensure employee cooperation – Workers should be informed of safety updates and compliance changes if they are interviewed.

Last but not least, you must strengthen your Respiratory Compliance Programs. Respiratory protection violations remain one of the most cited OSHA infractions. Employers should take this opportunity to update and reinforce their respiratory compliance programs.

a. Conduct Fit Testing – Ensure all workers required to wear respirators undergo OSHA-mandated fit testing.

b. Review Air Quality Monitoring – Reassess workplace exposure limits for airborne contaminants.

c. Improve PPE Accessibility – Verify that all employees have access to the correct respirators for their tasks.

d. Enhance Training – Provide workers with clear instructions on respirator use, maintenance, and storage.

IV. Answer Questions

Asking the right questions during the OSHA closing conference ensures that violations are properly understood, penalties are fair, and employers have a clear path forward. By addressing compliance concerns proactively, businesses can reduce risks, improve safety, and avoid future legal complications.

| Employer Question | Why It Matters |

|---|---|

| Were there any similar violations among other employers in our industry? | This helps businesses determine if they are facing common compliance challenges or if their violations are more serious compared to industry trends. |

| Are there any recommended best practices OSHA suggests beyond the minimum requirements? | Meeting the bare minimum may not always be enough. Employers can gain insight into proactive safety measures that go beyond regulatory compliance. |

| What factors could lead to reduced fines or alternative solutions? | OSHA sometimes offers penalty reductions, alternative corrective actions, or settlement options. Knowing these options helps ease financial burdens. |

| If corrections are already underway, can this affect the citation’s final status? | If an employer has started fixing issues before the citation is finalized, OSHA may consider lowering penalties or modifying the citation category. |

| Will this violation be classified as a repeat offense if a similar issue arises in the future? | Some citations escalate into repeat violations if the same issue happens again. Understanding how repeat status is determined helps employers prevent future higher fines. |

| What OSHA training programs or compliance resources are available to help us prevent future violations? | OSHA provides free consultation programs, hazard assessments, and safety training. Employers should take advantage of these to reduce future risks. |

| Are there any OSHA grants or funding programs available for workplace safety improvements? | Some industries qualify for OSHA grants that support workplace safety enhancements. Asking about funding options can help offset compliance costs. |

| What should be included in our internal safety audits to ensure ongoing compliance? | Knowing what OSHA looks for allows businesses to align internal audits with official regulatory standards and stay ahead of future inspections. |

| How often does OSHA update its standards, and what’s the best way to stay informed? | OSHA regularly revises its regulations. Employers should ask for recommended resources, mailing lists, or tools to keep up with policy changes. |

Addressing OSHA’s findings goes beyond penalty avoidance. It’s about ensuring a safer workplace and long-term compliance. Effective OSHA audit preparation and a structured approach to the closing conference allow employers to resolve uncertainties, correct violations efficiently, and reduce financial risks.

Consistently updating safety procedures and compliance programs helps businesses stay aligned with OSHA standards, protect employees, and prevent repeat violations.

Need expert support for OSHA respiratory compliance?

Respirator Clearance makes the process simple with fast, reliable online medical evaluations for respirator use.

Stay compliant—contact RespiratorClearance today!