Before any workstations are inspected or documents reviewed, an OSHA audit opening conference marks the official start of the process. This initial meeting sets the tone and expectations between the compliance officer and the employer, laying the groundwork for the rest of the inspection.

It’s where the inspector outlines the purpose of the visit, discusses procedures, and confirms what areas will be examined. Think of it as the briefing before a major project–the more clarity established at the beginning, the fewer surprises along the way.

This step is not just administrative; it directly influences the flow of the inspection. Businesses that approach it with preparation and transparency can foster a cooperative atmosphere, ensuring inspectors receive the information they need without unnecessary delays.

From verifying credentials to defining the scope, this discussion provides an opportunity for employers to ask questions and ensure their rights are recognized.

A well-managed opening conference signals that a company takes compliance seriously. It’s not just about following regulations–it’s about showing an active commitment to workplace safety.

How an employer handles this first stage can set the tone for everything that follows, making it either a structured process or a stressful uphill battle.

I. Presentation of Credentials

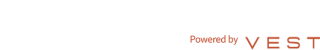

Before an OSHA audit officially begins, compliance officers are required to present their credentials. This is not just a formality; it’s a legal safeguard ensuring authorized personnel conduct inspections. Employers have the right to verify the inspector’s identity, understand their jurisdiction, and confirm that the audit follows proper procedures.

Skipping this step or overlooking the details could lead to confusion or even allow unauthorized individuals to misrepresent OSHA. By checking credentials, businesses can establish clarity from the start and ensure the inspection proceeds under the correct authority.

Verifying Identity

OSHA inspectors carry official identification, including their name, photograph, and unique credentials. Employers should always request to see these details before the inspection begins.

A legitimate inspector will have no issue providing this information, and businesses should compare the credentials against OSHA’s official standards.

Additionally, businesses should contact their local OSHA office for verification if there’s any doubt about an inspector’s legitimacy.

Scams and impersonations have been reported in various industries, and verifying identity ensures companies engage with a legitimate government representative. Employers should also keep a record of the inspector’s details in case follow-ups are needed later.

Establishing Authority

Beyond verifying identity, businesses must understand the scope of an OSHA inspector’s authority. Inspectors are assigned to specific regions and industries, and their ability to enforce regulations comes from federal guidelines.

Employers should ask about the purpose of the inspection and whether it stems from:

(A) a routine check

(B) a complaint, or

(C) a specific hazard report

Understanding why OSHA is there can help businesses focus their responses and prepare relevant documents.

Another key consideration is whether the inspector has any specialized authority related to industrial hygiene, hazardous materials, or workplace injuries.

Different OSHA officers may have different expertise, and knowing their role can help businesses prepare for more technical aspects of the audit.

While OSHA has the authority to inspect workplaces, employers have the right to request clarification on several key points before proceeding. This includes:

- The reason for the inspection (routine, complaint-driven, or incident-related).

- The standards being evaluated (specific safety guidelines being checked).

- Any documentation the inspector needs to review (logs, safety reports, training records).

If an employer has serious concerns about the inspection, they can request a delay until they have legal counsel present. However, delaying without valid reasoning could result in a warrant being issued, leading to a more thorough investigation.

Understanding Employer Rights

While OSHA has the authority to inspect workplaces, employers have the right to request clarification on several key points before proceeding. This includes:

- The reason for the inspection (routine, complaint-driven, or incident-related).

- The standards being evaluated (specific safety guidelines being checked).

- Any documentation the inspector needs to review (logs, safety reports, training records).

If an employer has serious concerns about the inspection, they can request a delay until they have legal counsel present. However, delaying without valid reasoning could result in a warrant being issued, leading to a more thorough investigation.

Setting the Tone

The way an employer interacts with an OSHA inspector in the first few minutes can set the stage for the entire audit. A calm, professional, and cooperative approach helps create an inspection that remains focused and structured.

Rushed, dismissive, or confrontational behavior could raise red flags and prompt a deeper investigation. Instead, businesses should assign a knowledgeable representative to greet the inspector, verify credentials, and facilitate the process.

Keeping interactions professional from the start makes communicating and addressing concerns easier as the audit progresses.

II. Explanation of Inspection Scope

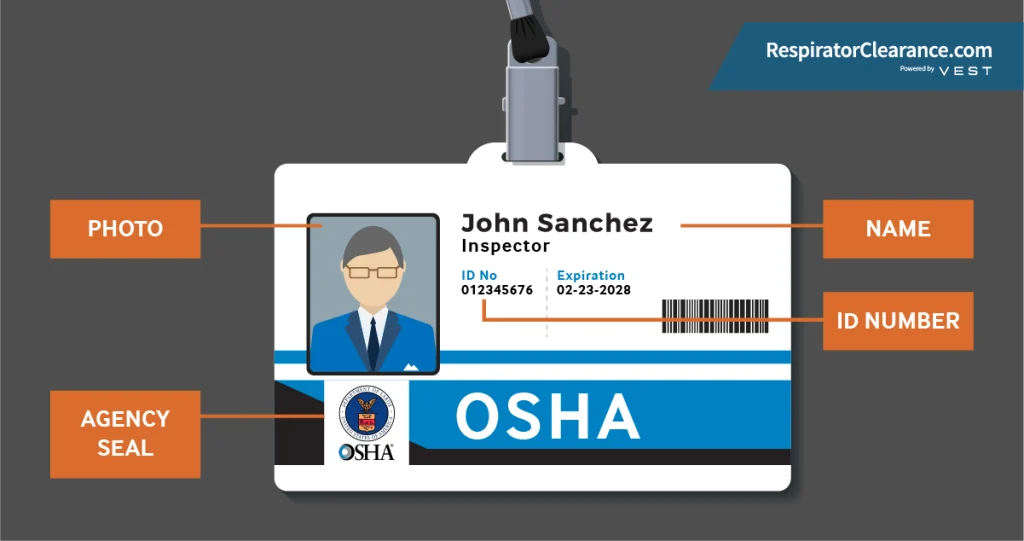

Before an OSHA inspector starts reviewing safety practices, they must explain why the workplace was selected for an audit. This isn’t a random visit. Specific factors trigger inspections, and understanding the reason can help businesses respond appropriately.

Employers should pay close attention to this explanation, whether it’s part of a routine check, a complaint-based investigation, or a targeted enforcement effort. To help you clarify your thoughts, ask yourself:

FIRST QUESTION: “Why Was My Business Selected?”

OSHA inspections fall into three primary categories:

- Routine Inspections

- These are planned visits to ensure general compliance with safety regulations.

- Complaint-Based Investigations

- If an employee or third-party files a formal safety complaint, OSHA may conduct an inspection to verify concerns.

- Targeted Industry Audits

- High-risk industries, such as construction or manufacturing, may be subject to scheduled inspections due to past violations or safety trends.

Employers should listen carefully to the stated reason and ask for clarification if necessary. If the inspection stems from a complaint, they have the right to know the nature of the issue, without necessarily receiving the complainant’s identity.

SECOND QUESTION: “What’s Being Inspected?”

Once the reason for the inspection is established, OSHA will clarify what areas, equipment, and records will be reviewed. Some inspections focus on specific hazards, while others examine overall workplace conditions. Common points of inspection include:

- Safety Procedures – Emergency exits, fire prevention measures, and PPE compliance.

- Equipment and Machinery – Proper maintenance, hazard controls, operational safety.

- Workplace Records – OSHA logs, training documentation, injury reports.

Employers should take notes on the inspector’s focus areas. If certain aspects of the business are not included in the scope, it’s helpful to clarify this upfront to avoid unnecessary disruptions.

THIRD QUESTION: “How does the Inspection Proceed?”

The inspection itself follows a structured process that includes a physical walkthrough, employee interactions, and hazard evaluations.

First, Walkthrough Process. The inspector will tour the workplace, observing operations and identifying potential hazards. Employers should ensure that work areas are clean, safe, and compliant with OSHA standards before the inspection.

Second, Employee Interactions. OSHA has the right to speak with employees to gain insight into workplace conditions. These interviews can be one-on-one or group discussions, and employees should feel free to share safety concerns without fear of retaliation.

Lastly, Hazard Assessments. Inspectors will evaluate potential risks, including air quality, noise levels, chemical exposure, and machine safety. If issues are identified, businesses may be required to correct them immediately.

FOURTH QUESTION: “Who Speaks for the Workforce?”

During an OSHA inspection, employees have the right to representation, ensuring their voices are included in the process. This means to say:

- They have Unionized Workplaces where a union representative may accompany the inspector.

- Alternatively, they have Non-unionized Workplaces, allowing employees to select a representative to be present during discussions.

- Also, some Private Interviews where OSHA can speak with employees confidentially to gather feedback on workplace conditions.

Employers cannot interfere with these interviews, nor can they retaliate against employees for participating. Instead, they should ensure workers are aware of their rights and encourage open communication.

III. Discussion of Procedures

Once the OSHA inspection begins, compliance officers systematically assess workplace conditions, speak with employees, review records, and verify adherence to safety protocols. Each step has a clear purpose, and knowing what inspectors look for helps businesses stay prepared and proactive.

| Inspection Step | What the Inspector Looks For | Employer’s Responsibilities | How to Prepare |

|---|---|---|---|

| Walkthrough Process | Workplace hazards, PPE compliance, and safety procedures | Ensure a safe, clean environment and correct hazards in advance | Conduct an internal walkthrough and fix obvious safety issues |

| Employee Interviews | Employee knowledge of safety rules, concerns about hazards | Allow private interviews and avoid retaliation | Educate workers on safety procedures and OSHA rights |

| Sampling and Testing | Air quality, noise levels, and chemical exposure | Cooperate with sampling procedures and provide necessary data | Maintain air quality reports and ensure hazard controls are working |

| Documentation Review | Injury logs, safety training records, hazard reports | Present requested records promptly and ensure accuracy | Keep OSHA Form 300 logs, training certifications, and audits up to date |

| Safety Protocols | Proper use of PPE, emergency procedures, hazard controls | Demonstrate active compliance with OSHA safety standards | Regularly train employees on PPE use and emergency actions |

| Machine and Equipment Safety | Guarding, lockout/tagout procedures, maintenance records | Ensure all machines are safe to operate and meet compliance | Conduct equipment safety inspections and document maintenance |

| Emergency Preparedness | Fire exits, alarm systems, evacuation procedures | Confirm emergency plans are in place and communicated | Run emergency drills and verify fire extinguishers and exits |

| Chemical and Hazardous Material Handling | Proper storage, labeling, and safety data sheets (SDS) | Maintain correct labeling and provide safety training | Store hazardous materials correctly and update SDS files |

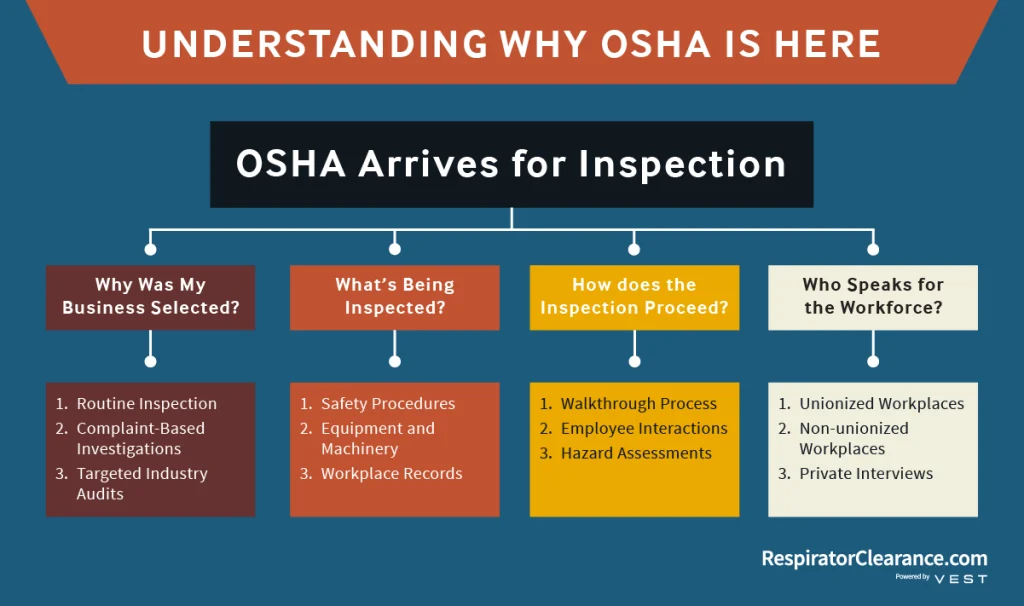

IV. Employee Representation

Employee representation in an OSHA audit is more than just a legal formality–it’s an essential part of the process that ensures a full and accurate assessment of workplace safety.

While previous sections have outlined how inspectors interact with employees, this section focuses on what businesses should do to properly manage employee participation in a way that is both compliant and constructive.

Step 1: Selecting a Representative Who Knows the Workplace

A strong employee representative isn’t just someone chosen at random. The best representatives are those who are familiar with workplace conditions, safety protocols, and previous incidents.

Employers should ensure that workers understand their right to choose someone who can effectively communicate their concerns–whether it’s a union official, safety coordinator, or a knowledgeable team member.

In situations where no representative is designated, employers should prepare for direct employee interviews, ensuring that workers feel informed about their rights and the purpose of their involvement.

Any hesitation or confusion about representation can create unnecessary tension, so businesses should clarify expectations early.

Step 2: Structuring the Representative’s Role to Benefit the Inspection

Rather than seeing the employee representative as an external observer, businesses should recognize their role as a source of valuable, work-specific insights. The representative is not just accompanying the inspector—they actively guide the conversation, point out areas of concern, and help ensure that real workplace conditions are accurately documented.

Employers should facilitate this by providing necessary access to documentation, hazard reports, and safety records so that the representative can contribute meaningfully. This helps the inspection proceed smoothly and demonstrates a commitment to transparency and workplace safety.

Step 3: Managing Employee Interviews Without Interference

As highlighted in the previous section, employee interviews are private and cannot be influenced by employers. However, businesses still play a role in helping employees understand the process and ensuring they feel comfortable participating.

This doesn’t mean coaching workers on what to say—it means reinforcing that the interviews are a standard part of the audit and that employees should answer honestly and confidently.

Employers can support this by:

- Clearly explaining that employees have the right to be interviewed confidentially.

- Providing a neutral space where interviews can take place without discomfort.

- Reassuring workers that their input won’t result in retaliation—which is legally prohibited but still a common fear.

If employees feel uneasy about the process, it may indicate broader workplace culture issues that should be addressed beyond the audit itself.

Step 4: Creating a Culture of Transparency That Extends Beyond the Audit

Ensuring a smooth OSHA audit isn’t just about getting through the inspection—it’s about fostering a work environment where employees regularly participate in safety discussions.

This means taking what’s learned in the audit and using it to strengthen internal safety programs.

Employers should encourage post-audit feedback from employees, using their experiences with OSHA to identify areas where communication can improve.

An effective audit process isn’t just about passing inspections—it’s about making safety a continuous conversation, not just an obligation when OSHA is present.

V. Review of Documentation

When OSHA arrives for an inspection, they aren’t just looking at workplace conditions—they want proof that safety procedures are followed and recorded properly. Inspectors will request documents that track injuries, training, policies, and past compliance issues.

Gaps in records, missing signatures, or outdated information can trigger citations or further investigation. Keeping everything accurate, organized, and secure ensures a smooth audit.

Required Documents: OSHA’s Essential Paperwork

OSHA inspectors will request specific records that serve as the foundation for compliance. Businesses must have the following readily available:

Without these records, businesses may face penalties or further scrutiny.

Accuracy & Completeness: Avoiding Gaps in Documentation

Inspectors don’t just check for documents–they examine their accuracy to ensure compliance. They look for:

Even minor mistakes, like missing signatures or inconsistent dates, can result in violations or additional questions from inspectors.

Accessibility: Presenting Documents Efficiently

OSHA expects documents to be immediately available upon request. Employers should:

Slow responses or misplaced documents may raise concerns about overall compliance.

Confidentiality: Protecting Employee & Business Data

Not all OSHA-related records should be openly accessible. Certain documents, especially those containing medical or personal employee information, must be kept private and only shared with authorized personnel.

A well-managed Opening Conference sets the stage for a structured and efficient OSHA audit. Ensuring that credentials are verified, the inspection scope is clear, employees are represented, and documentation is in order can make a significant difference in the process.

Businesses that prepare in advance reduce the risk of violations and keep inspections on track.

Ready for a Smooth OSHA Audit Opening Conference?

If you’re unsure whether your business is fully prepared for an OSHA audit, Respirator Clearance can help. Our team provides expert guidance on compliance, documentation, and workplace safety.

Contact us today to ensure your next audit runs smoothly and without unnecessary stress.

For more information or a consultation, visit Respirator Clearance.