The OSHA audit is done, but your work isn’t over. If you’re wondering what happens after the inspector leaves, you’re not alone. The next steps are where savvy safety teams distinguish themselves and avoid the headaches of missed deadlines or overlooked fixes.

This is the moment to turn that audit into action. Occupational Safety and Health Administration (OSHA) citations don’t have to mean chaos–especially if you know how to respond quickly and correctly. Fix the issue, file the right paperwork, and stay off their radar next time.

Respiratory protection often tops the list of common violations. Whether it’s skipped fit testing, improper equipment use, or a missing written plan, this area tends to raise red flags. Now’s your moment to correct the course, not just for compliance, but for peace of mind.

I. Reading Between the Lines of Your OSHA Citation

Before you fix a problem, you have to understand it fully, and that starts with knowing exactly what OSHA just handed you. This section breaks down how to read a citation the way OSHA expects you to respond: carefully, clearly, and with purpose.

What Your OSHA Audit Citation Actually Says

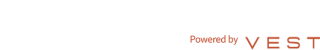

When OSHA issues a citation, it’s more than just a fine. It’s a formal notice of where your safety practices missed the mark. You’ll typically find the type of violation listed below: Each of these carries different weight in terms of legal and financial consequences, according to OSHA:

- A Willful violation means OSHA believes you knew a hazard existed and chose not to correct it. For example, failing to provide respirators to workers in a known silica exposure area could fall under this category.

- A Repeat violation is issued when a company is cited for the same issue across different inspections, such as missing respirator fit testing records at two separate facilities.

- A Serious violation indicates that there was a substantial probability of serious harm or even death, such as not conducting medical evaluations before assigning respirators.

- An Other-than-Serious violation might include paperwork-related gaps, like incomplete training records or a missing program update. These are still enforceable but typically carry minor fines.

Alongside the violation type, you’ll also see the specific standard breached, usually citing a regulation like 29 CFR 1910.134. Lastly, abatement deadlines are provided, giving you a fixed number of days to correct the issue and prove it’s been resolved.

Skimming this document is a mistake. Every word matters. Think of it like a contract–except the terms have already been decided, and the clock is ticking.

Decoding the OSHA Citation Language

Some citations are written in bureaucratic code, but don’t let that slow you down. These phrases point directly to what went wrong and what OSHA expects to see fixed.

The following helps you assess how urgent and risky the issue is:

1. Keywords for Willful

2. Keywords for Repeat

Keywords for Serious

Keywords for Other-than-Serious

Grouped violations can be a red flag or a relief. Sometimes OSHA consolidates related issues (like multiple respirator deficiencies) into a single line item. This can reduce fines, but it may also signal a systemic problem they want you to address.

If any part of the citation feels unclear, this is the moment to bring in your Environment, Health, and Safety (EHS) lead, legal counsel, or safety consultant. The sooner you know what you’re really dealing with, the sooner you can fix it.

Why Respiratory Citations Demand Immediate Focus

Citations tied to respiratory protection—like those under 29 CFR 1910.134—are rarely minor. These often involve missed fit tests, unapproved equipment, or a lack of a written program. Beyond compliance, these issues directly affect worker health and liability. In fact, OSHA routinely lists respiratory protection among the top 10 violations year after year.

If your citation references this standard, take it seriously. It signals that your workers were at risk for exposure to harmful airborne contaminants–and that your safety protocols didn’t hold up. Your next steps should be swift, documented, and centered on fixing these gaps for good.

II. Correct OSHA Violations the Right Way

The next step is clear once you’ve read the citation: fix what’s broken quickly. But not all violations are equal, and how you correct them says just as much as catching them in the first place.

Start with the Biggest Threats First

Not all violations carry the same weight, and OSHA expects you to act accordingly. Start with anything flagged as Willful, Repeat, or Serious. These are the issues most likely to lead to high fines, follow-up inspections, or worse, actual harm to your team.

If your respiratory program was hit with any of these, it’s time to act decisively. Start documenting corrections immediately. These top-tier violations aren’t just regulatory red flags but red alerts for your safety culture.

Correct Respiratory Program Gaps

Many violations tied to 29 CFR 1910.134 come down to missing or outdated protocols. If your written respiratory protection program doesn’t reflect actual practices, or worse, doesn’t exist–OSHA will see that as a major gap. Other common issues? No medical evaluations, outdated training records, skipped annual fit tests, or workers using facial hair with tight-fitting masks.

Here’s where to start:

Get Help if You Need It—You’re Not Alone

Some corrections can’t be handled by one person or department. If your team lacks the expertise or bandwidth, bring in outside help. Industrial hygienists, third-party safety consultants, or even your state’s OSHA consultation services can provide quick guidance or formal assistance, often without triggering enforcement.

Internally, get your safety coordinator, HR, and department leads involved. Each plays a role in documenting changes, retraining staff, and following up. You don’t have to handle it all solo, but you do have to make sure it gets done.

III. Document OSHA Abatement the Right Way

Fixing the violation is only half the job. Now, you need to prove it. OSHA wants to see clear, timestamped evidence that you didn’t just patch things up–you fixed them the right way.

| Actionable Steps | What You Need to Do | How to Prove It | Pro Tips for Respiratory Violations |

|---|---|---|---|

| 1. Fix the Hazard | Correct the issue OSHA flagged—whether that’s equipment, training, or program-related. | Take clear, dated photos or videos of the corrected condition or procedure in action. | Document fit testing being conducted, new respirator distribution, or updated PPE access points. |

| 2. Update Written Procedures | Revise the written respiratory protection plan and relevant SOPs. Make sure they match what’s actually being practiced. | Save version history, show updated pages, and include signatures from reviewers. | Highlight changes like hazard assessments, new roles, or added safety steps tied to 29 CFR 1910.134. |

| 3. Collect Supporting Evidence | Gather invoices, rosters, internal memos, or service logs that prove action was taken. | Scan receipts, attach signed training logs, and include third-party reports where applicable. | Track who was trained, when, and on what—especially for respirator use, maintenance, and limitations. |

| 4. Submit Required Forms | File any documentation OSHA asks for—this often includes a letter of corrective action or Form 300A. | Bundle your evidence with a cover summary to make it easy for the inspector to review. | Include respirator fit test records, medical clearance letters, and written program updates in your packet. |

| 5. Store Everything Accessibly | Organize all abatement documentation in one place—physical or digital. | Use a shared drive, binder system, or EHS software so it’s easy to find later. | Keep all respiratory compliance records in a single location with backups. |

| 6. Be Ready for Follow-Up | OSHA may return to verify corrections—don’t treat abatement as a one-and-done task. | Schedule internal check-ins or mock audits to ensure long-term compliance. | Set reminders for annual fit testing, medical evaluations, and policy reviews to stay ahead of re-inspections. |

IV. Contest an OSHA Citation (If Applicable)

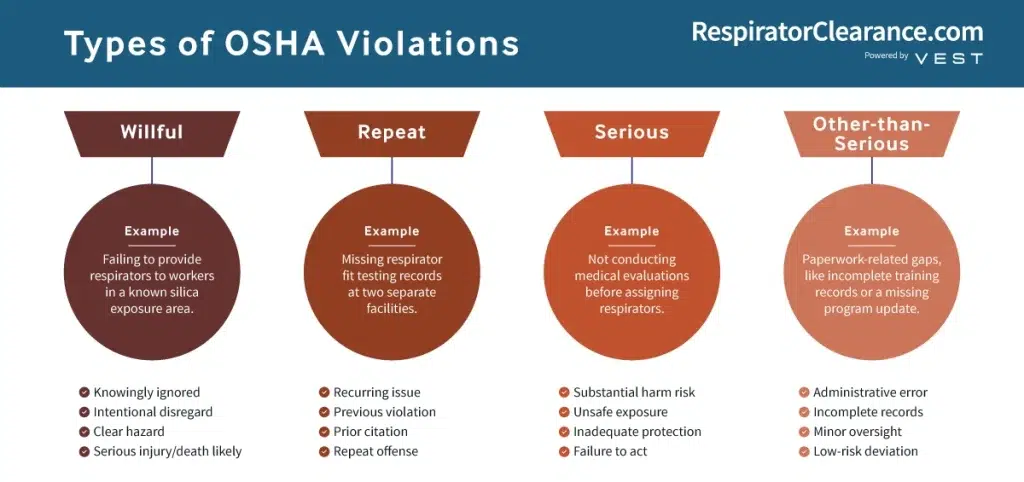

Sometimes, OSHA gets it wrong or at the very least, not the full picture. If you believe a citation was unfair, unclear, or doesn’t reflect the actual conditions on-site, you have the right to contest it. But the clock is ticking, and there’s a process to follow.

Step 1: Decide If It’s Worth Fighting

Not every citation is worth contesting—but some are. If you believe the violation was based on incorrect facts, misinterpreted evidence, or doesn’t apply to your operations, it might be time to push back. For instance, if OSHA cited you for not having a written respiratory program, but you have a current version and training records to back it up, that’s something you can—and should—defend.

Before moving forward, ask yourself:

- Is the citation factually inaccurate?

- Does it misrepresent the severity or type of hazard?

- Would accepting it create long-term regulatory or legal consequences (especially for “Willful” or “Repeat” labels)?

This isn’t about avoiding accountability—it’s about accuracy. If the citation doesn’t reflect reality, challenge it.

Step 2: File a Notice of Contest Fast

You only have 15 working days from the time you receive the citation to formally contest it. That’s not a lot of time, so don’t sit on the decision. Here’s what to do:

- Draft a written Notice of Contest (a simple letter is enough) stating which parts of the citation you’re challenging—this could be the violation itself, the classification, the fine amount, or the abatement date.

- Send it to the OSHA area director listed on your citation via certified mail or hand delivery—no email, no verbal notifications.

- Keep a dated copy for your own records.

If you miss the deadline, the citation becomes final—whether it’s accurate or not.

Step 3: Bring in Legal and Safety Support

Once the notice is filed, it’s time to build your case. You don’t have to do it alone—and you shouldn’t.

Bring in:

- Your company’s legal counsel (or outside representation)

- A certified safety consultant

- Your internal EHS or compliance lead

Step 4: Use Defense Strategies That Work for Respiratory Citations

Respiratory violations can be highly technical, and your defense should be specific. Some strategies that have worked in real cases include:

- Showing that fit testing or training was completed, but it was just not documented properly at the time.

- Proving that the cited hazard didn’t apply to the job or the exposure level present.

- Demonstrating corrective actions were already underway before the citation.

- Clarifying how your program meets the intent of the standard, even if a detail was missed.

Always support your defense with documentation, not just statements. If OSHA missed part of the story, now’s your chance to fill in the gaps.

V. Your Checklist for Preventing Repeat Violations

Now that the audit is behind you, it’s time to focus on the one thing OSHA really wants to see next: no repeat issues. Prevention starts with understanding what went wrong, and building better habits into your day-to-day operations.

1. Conduct a Root Cause Analysis

Get to the actual reason the violation happened—not just what was written on the citation.

- Interview the employees involved in the task or area.

- Identify what was missing (procedure, training, supervision, or time).

- Review whether the equipment was available, accessible, and working.

- Check if the issue was raised before but ignored or misunderstood.

- Look for patterns in previous audits, near-misses, or internal reports.

- Document the findings and share them with supervisors or leads.

2. Update the Respiratory Protection Program

Make sure your written program reflects reality–not just the version saved two years ago.

- Add any new roles, processes, or job functions that involve respirator use.

- Confirm that the respirator types listed match what’s currently issued.

- Update procedures for cleaning, storing, and inspecting equipment.

- Include medical evaluation and fit testing timelines clearly.

- Make the plan available to all employees–not just managers.

- Add revision dates to track when updates were made.

3. Reinforce Training and Fit Testing

Training isn’t one-and-done–especially when lives and lungs are at stake.

- Schedule annual fit tests and track expiration dates for each employee.

- Provide hands-on training for new hires during onboarding.

- Run refresher sessions after any program update or new equipment rollout.

- Quiz employees periodically to make sure information is retained.

- Train supervisors to spot incorrect respirator use on the floor.

- Make records easy to access during audits—sign-ins, dates, and topics covered.

4. Perform Regular Internal Audits

Audit yourself the way OSHA would and fix the little stuff before it grows.

- Use an internal checklist based on 29 CFR 1910.134.

- Walk the floor monthly and spot-check respirator use and condition.

- Review written records quarterly for completeness and accuracy.

- Interview a random sample of workers about procedures and awareness.

- Test emergency protocols, like what happens during a cartridge failure.

- Track and resolve all findings before the next cycle begins.

5. Build a Compliance-First Culture

The best safety programs are built into behavior–not taped to the breakroom wall.

- Start toolbox talks with real examples of good practices (and close calls).

- Recognize employees who report hazards or suggest improvements.

- Create a no-retaliation rule for reporting safety concerns.

- Invite field staff to help review or test new procedures.

- Safety should be included in performance evaluations, not just production.

- Let your team know that compliance isn’t paperwork–it’s protection.

From reviewing your citation to correcting violations, documenting fixes, and putting prevention into practice–what you do after an OSHA audit can shape the future of your safety program. Don’t wait for another OSHA inspection to get it right. Start building better habits now to stay OSHA compliant.

Looking for the next steps?

Download our free OSHA Respiratory Protection Checklist to stay organized and ready–this time and next time with Respirator Clearance.

Your team’s safety isn’t paperwork. It’s daily work. Contact Respirator Clearance today!