Some see OSHA audits as a bureaucratic headache—a checklist of safety rules and penalties waiting to happen. Others recognize them as a critical safeguard, ensuring workplaces remain safe, compliant, and free from preventable hazards.

The truth lies somewhere in between–while the systematic process can feel overwhelming, it serves a purpose that no business can afford to ignore.

OSHA’s Respiratory Protection Standard or RPS (29 CFR 1910.134) is one of the most closely monitored regulations for industries dealing with airborne hazards. Failure to comply doesn’t just invite hefty fines or legal trouble–it puts workers at risk, exposing them to serious health concerns that could have been avoided.

An audit isn’t just about passing an inspection; it’s about proving that your business values safety as much as productivity.

The key to handling an OSHA audit isn’t just understanding what’s required–it’s about being prepared before an inspector ever steps through the door. From knowing the regulations to maintaining up-to-date records, every step plays a role in ensuring a smooth, issue-free review.

Businesses that take a proactive approach don’t just reduce their risk of violations; they build a culture of safety that benefits their workforce and long-term operations.

I. Preparation

No business wants to be caught off guard during an OSHA audit. Following key steps in compliance audits allow businesses to ensure that when an inspector arrives, they’re ready. Audit Preparation isn’t just about having the right documents in place but also building a workplace where safety is second nature.

Understand OSHA Standards

Knowing what OSHA (Occupational Safety and Health Administration) expects is the first step toward compliance. Regulations vary by industry, but one rule applies across the board: businesses must identify workplace safety hazards and implement measures to protect employees. For companies dealing with airborne contaminants, this includes strict adherence to the Respiratory Protection Standard.

Employers should regularly review OSHA’s official guidelines, industry updates, and past citations within their sector to stay ahead of potential compliance issues. Failing to understand these regulations is one of the easiest ways to invite violations—knowledge is the best defense.

Conduct Internal Audits

An internal audit serves as a test run for an official inspection. By proactively assessing workplace safety, businesses can spot risks before they become OSHA violations. These audits should include facility inspections, employee interviews, and a review of training and documentation.

Hazards don’t always present themselves as obvious dangers. Something as simple as a poorly stored chemical, an outdated respirator fit test, or improper PPE usage could result in a citation. Regular audits help catch these issues early and provide time for corrective action.

Maintain Documentation

OSHA inspectors don’t just check the workplace. They also check records that prove compliance. Missing or outdated paperwork can lead to hefty fines, even if a business follows safety procedures correctly.

Key documents to maintain include:

Organizing these records in a centralized, easily accessible system ensures that there’s no scrambling to find the necessary paperwork when an audit happens.

Employee Training

A workplace is only as safe as the people working in it. Training employees on OSHA standards, proper equipment use, and emergency procedures is a requirement—not an option.

For respiratory compliance, this means ensuring workers:

Training shouldn’t be a one-time event. Annual refresher courses and real-world drills help reinforce workplace safety culture and keep employees informed about regulatory updates.

Designate a Safety Coordinator

Having a dedicated point of contact for workplace safety ensures that compliance efforts stay on track. A safety coordinator is responsible for:

This person doesn’t have to be a standalone hire. Few businesses assign this role to HR managers, facility supervisors, or team leaders.

The goal is to have someone who understands OSHA regulations and can address compliance concerns before they escalate.

Prepare for the Walkthrough

When an OSHA inspector arrives, they will conduct a walkthrough of the workplace to assess conditions firsthand. Businesses can prevent last-minute panic by conducting their own pre-inspection checks, ensuring all safety measures are in place.

Key areas to review:

Know Your Rights

Many businesses are unaware that OSHA audits come with employer rights, and understanding these rights can significantly affect how an inspection plays out. Employers have the right to request an inspector’s credentials before allowing the audit to proceed and can ask for clarification on the scope of the inspection to ensure it remains within proper boundaries.

Throughout the process, the employer or a designated representative is allowed to accompany the inspector to observe and provide necessary context for the worksite conditions.

At the conclusion of the audit, businesses have the right to a closing conference, where the inspector will explain any findings and potential violations. If citations are issued, companies can contest them through a formal appeals process if they believe they were unfairly assessed.

Knowing and exercising these rights allows businesses to participate more actively in the audit process, ensuring they receive a fair evaluation.

II. Opening Conference

The opening conference is where everything begins. It’s the moment when OSHA inspectors lay out the details of the audit, explain what they’ll be reviewing, and set expectations for the inspection process. This initial meeting isn’t just a formality but a critical opportunity for businesses to understand what’s ahead and ensure the audit proceeds smoothly.

Presentation of Credentials

Before the audit starts, the inspector is required to present official identification proving their authority to conduct the inspection. Employers have the right to verify these credentials before allowing access to the worksite. This step ensures that businesses aren’t caught off guard by fraudulent inspections or unauthorized personnel attempting to gain access.

It’s a good practice for businesses to train front-desk staff or security teams to verify OSHA credentials properly. If there are any doubts, companies can contact the nearest OSHA office to confirm the inspector’s identity before proceeding.

Explanation of Inspection Scope

Once credentials are verified, the inspector will explain why the audit is taking place and what areas will be reviewed. This could be due to a random inspection, an employee complaint, a reported incident, or an industry-wide enforcement initiative.

Understanding the reason behind the audit can help businesses focus on key compliance areas and anticipate what the inspector will be looking for.

The inspector will outline whether the audit will be a general review of workplace safety or a targeted inspection focusing on a specific concern, such as respiratory protection compliance. Businesses should use this moment to ask clarifying questions to ensure they fully understand the scope of the review.

Discussion of Procedures

The inspector will then provide a step-by-step overview of how the audit will proceed. This includes:

- Conducting a workplace walkthrough to identify potential hazards.

- Reviewing documentation related to safety training, equipment maintenance, and past violations.

- Interviewing employees to assess their knowledge of workplace safety protocols.

This discussion allows businesses to prepare for what’s coming and ensure that the right personnel and documentation are available when needed. Employers should also take this opportunity to confirm whether sampling or environmental testing will be conducted, especially if respiratory hazards are a focus of the audit.

Employee Representation

Workers play a key role in OSHA audits, and employees have the right to be involved in the inspection process. A designated employee representative—whether a safety committee member, a union representative, or a worker familiar with safety protocols—can accompany the inspector during the walkthrough.

If employees choose not to have a representative, the inspector may interview workers privately to get firsthand insight into workplace conditions. Employers should ensure that employees feel comfortable answering questions honestly and are aware of their rights when speaking with OSHA officials.

Review of Documentation

Before moving on to the walkthrough, the inspector will typically request specific safety records for review. These may include:

- Respiratory protection training logs and fit-test records.

- Hazard assessments identifying potential risks in the workplace.

- Records of past OSHA violations and corrective actions taken.

- Employee medical evaluations for respirator use.

Having these documents organized and easily accessible can prevent unnecessary delays and demonstrate that the company takes compliance seriously. If certain records aren’t immediately available, the inspector may allow additional time to produce them, but missing or incomplete documentation could lead to citations.

III. Walkthrough

Once the opening conference wraps up, the inspector moves on to the walkthrough–the part of the audit where workplace conditions are assessed in real time. This is where safety protocols, equipment maintenance, and employee practices are put under the microscope. The goal isn’t just to find violations but to ensure the workplace meets OSHA’s safety standards.

1) Defining the Scope

Before diving into specific checks, the inspector will outline which areas of the workplace will be reviewed. This depends on the types of safety audits—some inspections focus on specific complaints or hazards, while others involve a full safety assessment.

During this phase, businesses should ensure that all work areas, equipment, and safety documents are accessible. If an inspection is limited to a certain department or safety concern, managers should confirm this with the inspector to avoid unnecessary disruptions.

2) Identifying Hazards

Once the scope is clear, the inspector begins identifying potential risks in the workplace. This includes:

- Checking machinery and equipment for proper guards and maintenance.

- Ensuring respiratory protection and PPE are being used correctly.

- Inspecting chemical storage and ventilation systems for compliance.

- Looking for trip hazards, electrical risks, and emergency exit accessibility.

Even minor issues–like a cluttered workspace or a missing safety sign–can be flagged as violations. Businesses should conduct their own internal safety audits to catch these problems before an OSHA inspector does.

3) Employee Interviews

The inspector will speak with employees to get a firsthand perspective on workplace conditions. These interviews help determine whether workers understand safety procedures and feel comfortable reporting hazards.

Employees may be asked questions like:

- Have you received training on respiratory protection and PPE use?

- Do you know how to report a workplace hazard or injury?

- Have you experienced unsafe conditions that haven’t been addressed?

Interviews are confidential, and employers are not permitted to influence employee responses. To prepare, businesses should ensure that workers receive regular training and clear communication about workplace safety.

4) Sampling and Testing

The inspector may conduct sampling and exposure testing depending on the industry and work environment. This is especially important for businesses dealing with airborne contaminants, noise exposure, or chemical hazards.

Common tests include:

a. Air quality assessments – Checking for harmful dust, fumes, or toxic gases.

b. Noise level measurements – Ensuring the workplace complies with OSHA’s hearing conservation standards.

c. Hazardous material sampling – Testing for chemical exposure risks.

If a workplace does not have current air sampling records or exposure assessments, the inspector may require them to be conducted. Businesses should stay ahead of this by performing their own periodic environmental testing.

5) Immediate Corrections

If a serious safety issue is identified during the walkthrough, the inspector may require immediate corrective action. This could include:

Addressing hazards immediately can sometimes prevent a formal citation. Employers should be prepared to take corrective actions during the inspection to show their commitment to workplace safety.

IV. Documentation Review

An OSHA audit doesn’t rely on workplace conditions alone—the records tell their own story. Inspectors examine documentation to ensure that safety programs aren’t just in place but are actively followed and maintained. Missing, outdated, or incomplete records can result in violations, even if a business is otherwise compliant.

| Key Area | What OSHA Reviews | Common Issues | Best Practices |

|---|---|---|---|

| Reviewing Required Documents | Employee medical evaluations, fit-test records, training logs, hazard assessments, PPE maintenance records. | Missing or expired records, lack of training logs. | Keep a digital or physical archive with labeled folders for quick retrieval. |

| Checking for Accuracy and Completeness | Dates, signatures, test results, compliance reports, inspection records. | Incomplete forms, missing signatures, outdated information. | Conduct quarterly audits to ensure all records are up to date. |

| Ensuring Accessibility | Documents should be readily available for OSHA review. | Hard-to-find paperwork, disorganized storage. | Store records in a centralized system for easy access. |

| Verifying Compliance | Comparing records with OSHA standards to ensure training and equipment checks align. | Safety programs exist on paper but are not being followed. | Perform routine safety meetings to verify that documentation reflects actual practices. |

| Implementing Continuous Improvement | Identifying record-keeping gaps and improving documentation processes. | Repeating errors in record-keeping, outdated safety policies. | Regularly review and refine documentation procedures to close compliance gaps. |

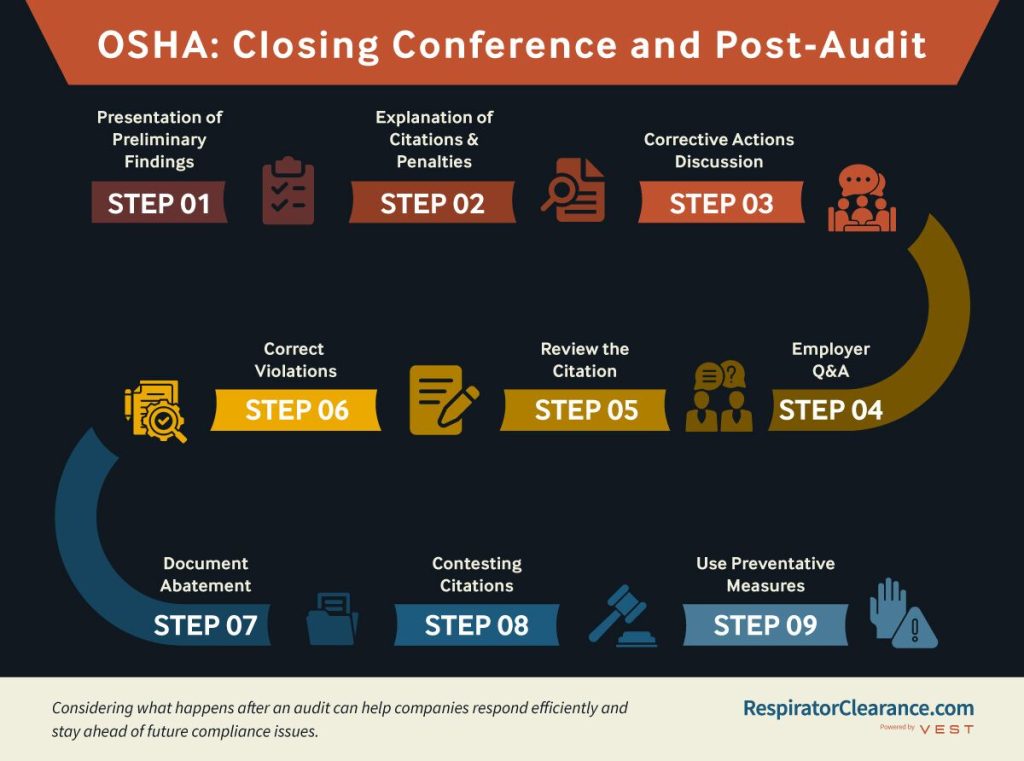

V. Closing Conference and Post-Audit

An OSHA inspection doesn’t end when the inspector leaves the job site. The final phase, which is the closing conference and post-audit actions, determines the next steps for businesses, whether that means fixing violations, disputing citations, or reinforcing workplace safety. Considering what happens after an audit can help companies respond efficiently and stay ahead of future compliance issues.

Once the inspection is complete, OSHA holds a closing conference to discuss initial findings, potential violations, and next steps. This is the company’s chance to clarify concerns and understand what corrective actions may be required.

Step 1. Presentation of Preliminary Findings

At the start of the conference, the OSHA inspector provides an overview of their observations. This includes:

- Areas where the business is meeting compliance standards

- Potential violations and workplace hazards identified

- Any immediate safety concerns that need urgent correction

This is not the official report but rather an informal review of findings before citations are formally issued. Employers should take notes and ask for clarifications if anything is unclear.

Step 2. Explanation of Citations & Penalties

If OSHA has found violations, the inspector will explain the type and severity of each issue. Citations fall into different categories:

- Serious Violations – Issues that pose a significant risk to employee safety.

- Willful Violations – When an employer knowingly ignores OSHA standards.

- Repeat Violations – Previously cited issues that have not been addressed.

- Other-than-Serious Violations – Compliance issues that may not cause immediate harm but still require correction.

Along with the citations, the inspector provides details on penalties or fines, which can vary based on the severity and history of past infractions.

Step 3. Corrective Actions Discussion

OSHA doesn’t just hand out violations. They also provide guidance on how to fix them. During this part of the closing conference, the inspector explains:

- Required corrective actions for each violation

- Deadlines for compliance (some corrections must be made immediately)

- Best practices to prevent future citations

This discussion is an opportunity to ask OSHA what documentation is required to prove corrective action and whether any violations might qualify for a penalty reduction if resolved quickly.

Step 4. Employer Q&A

Before the conference ends, employers have the opportunity to ask questions about the findings. Common topics include:

- How citations were determined

- What specific documentation is needed for compliance

- Whether there are options for reducing fines

- What to expect if violations are contested

Employers should take full advantage of this opportunity to gather information and clarify any remaining questions before moving on to post-audit actions.

Once the closing conference concludes, businesses must take action based on OSHA’s findings. The steps that follow will determine whether a company corrects violations, challenges citations, or strengthens safety protocols to prevent future issues.

Step 5. Review the Citation

Shortly after the closing conference, OSHA will issue an official citation letter outlining:

- The specific violations identified

- Any fines or penalties assigned

- Deadlines for correcting hazards or submitting proof of compliance

Employers should carefully review each citation and verify that OSHA’s findings align with the conditions observed during the audit. If anything seems incorrect, they may have grounds for a dispute.

Step 6. Correct Violations

The next step for businesses that accept the citations is to fix the violations within the timeframe OSHA provides. This could include:

- Providing additional safety training for employees

- Updating workplace policies and procedures

- Purchasing and maintaining proper PPE

- Repairing or replacing unsafe equipment

Some corrections may require compliance documentation, such as photos, training logs, or updated safety procedures.

Step 7. Document Abatement

Once violations are corrected, businesses must provide proof of compliance—a process known as abatement documentation. This may include:

OSHA requires businesses to submit abatement documentation by the deadline specified in the citation notice. Failing to do so could result in additional penalties.

Step 8. Contesting Citations

If an employer believes a citation was issued unfairly or inaccurately, they have the right to formally contest it. The appeal process involves:

(a) Submitting a Notice of Intent to Contest within 15 working days of receiving the citation

(b) Providing evidence or testimony explaining why the violation is incorrect

(c) Attending an informal OSHA conference to discuss the dispute

Challenging a citation doesn’t always mean avoiding penalties, but it can reduce fines or reclassify violations if OSHA finds the employer’s argument valid.

Step 9. Use Preventative Measures

The best way to avoid future OSHA violations is to proactively improve workplace safety. Companies that go beyond compliance requirements are far less likely to face repeated citations.

Key preventative measures include:

Learning from past inspections and prioritizing workplace safety can avoid costly penalties and create a safer environment for employees.

How RespiratorClearance Supports OSHA Compliance?

OSHA audits can be time-consuming and stressful, especially when businesses are unsure if their documentation and safety protocols meet regulatory standards. RespiratorClearance simplifies the process, ensuring companies stay compliant before, during, and after an inspection:

Pre-Audit Readiness

Preparation is key to passing an OSHA inspection. RespiratorClearance provides a structured compliance checklist, helping businesses identify potential gaps before an audit.

From conducting internal safety audits to offering expert-led training, companies get the tools to ensure their workplace meets regulatory compliance.

Workplace Safety & Documentation Support

Maintaining accurate records is just as important as workplace conditions.

RespiratorClearance digitizes compliance tracking, offering automated alerts for expiring certifications and a centralized platform for fit tests, training logs, and PPE records.

This ensures that businesses can produce the documentation when OSHA requests it instantly.

On-Site & Remote OSHA Audit Support

During an inspection, having the right guidance can prevent unnecessary penalties.

RespiratorClearance assists businesses in real-time, helping them understand what inspectors are looking for, how to respond to questions, and how to present documentation properly.

Post-Audit Compliance & Ongoing Safety Management

OSHA compliance doesn’t stop once the audit is over.

RespiratorClearance helps businesses address citations, file appeals if necessary, and implement long-term improvements to prevent repeat violations.

With continuous compliance monitoring, companies can stay audit-ready at all times.

OSHA audits can feel overwhelming, but safety professionals can turn them into a manageable process with the right approach. Prioritizing worker safety and compliance is a good idea—not only to avoid fines and legal issues but also to create a safer, more efficient workplace.

Staying ahead of regulations reduces risks, enhances operational efficiency, and ensures that safety measures become an integral part of daily operations rather than just written policies.

Are you ready for an audit?

Respirator Clearance provides the tools and guidance needed to simplify compliance and keep businesses audit-ready. Let RespiratorClearance help you stay compliant and prepared!

For more information or a consultation, contact Respirator Clearance.