The factory floor buzzed with activity as workers weaved and moved in between machines as the day’s tasks unfolded. Unbeknownst to them, an OSHA compliance officer had already begun the audit. He watched as a technician adjusted his mask.

At first, it was a routine motion until he noticed the poor seal. That tiny oversight wasn’t just a mistake; it was a violation that left an entire team exposed to hazardous fumes.

Moments like this are precisely why OSHA walkthroughs exist–not to control businesses, but to hold them accountable for worker safety.

Compliance officers don’t just scan documents; they observe actual working conditions, ensuring safety procedures are more than just policies on paper. Every unnoticed hazard, every ignored protocol, is a risk that can have real consequences.

With respiratory protection and workplace hazards under intense scrutiny, businesses must be prepared to demonstrate that safety isn’t just a legal requirement but a core commitment.

The walkthrough is a checkpoint where preparation meets reality, and cutting corners isn’t an option.

I. Scope of the OSHA Walkthrough

The OSHA walkthrough is where compliance is put to the test. Inspectors systematically move through a facility, examining safety conditions, reviewing records, and speaking with employees.

This stage determines whether a company’s safety protocols hold up under real-world scrutiny–or if there are gaps that put workers at risk.

The walkthrough phase is where safety is either confirmed or called into question.

Understanding the Scope of an OSHA Walkthrough

OSHA inspections are not random. Each walkthrough follows a structured approach, covering key areas of workplace safety.

The goal is to assess potential hazards, ensure compliance with Occupational Safety and Health standards, and verify that employees are trained and protected.

The scope may vary depending on industry risks, reported incidents, or specific complaints filed against a company.

Determining the Scope

Not all inspections cover an entire facility. Multiple factors shape the focus of a walkthrough, including

(a) employee complaints

(b) past violations, and

(c) the type of work being performed.

High-risk industries, such as manufacturing and chemical processing, are often subject to more thorough inspections due to their inherent dangers. Compliance officers also prioritize areas where prior issues were found, ensuring that corrective actions were implemented correctly.

Key Areas of Focus

Inspectors do not simply glance around a workspace. They strategically evaluate high-risk zones and safety-critical operations. These areas may include

(a) production floors

(b) confined spaces

(c) storage rooms with hazardous materials, and

(d) locations where heavy machinery is used.

Respiratory protection is a primary focus, particularly in workplaces with airborne contaminants. Inspectors check for proper ventilation, safe handling of hazardous substances, and adherence to personal protective equipment (PPE) protocols.

OSHA Standards That Apply

Specific OSHA regulations govern every industry; inspectors compare workplace conditions against these legal requirements. One of the most frequently cited standards is 29 CFR 1910.134, which outlines requirements for respiratory protection.

This rule mandates proper respirator selection, fit testing, and employee training to ensure workers are not exposed to harmful airborne substances. Other applicable standards may involve hazardous material handling, fall protection, and emergency response preparedness.

The Role of Documentation

Paperwork matters just as much as physical conditions. Inspectors review safety manuals, incident reports, and maintenance logs to confirm that companies are following OSHA guidelines.

A well-organized record system signals a proactive approach to safety, while missing or outdated documents can raise red flags.

Employers should have easily accessible records that prove compliance, including training logs, equipment maintenance records, and records of previous audits.

Employee Interviews and Safety Awareness

Compliance isn’t just about policies–it’s about people. Inspectors conduct interviews with workers to gauge their understanding of safety protocols and assess whether training programs are effective.

Employees may be asked about PPE usage, emergency procedures, and their ability to report safety concerns. These conversations help OSHA officers determine if safety measures are actively followed or merely written policies with no real enforcement.

II. Identifying Hazards

Hazards are not always obvious, and OSHA inspectors are trained to catch safety risks that employers or workers might overlook. Their goal is not just to enforce regulations but to prevent accidents, injuries, and long-term health issues.

Simply understanding what inspectors look for, businesses can take proactive steps to create a safer workplace before an official audit takes place.

Inspectors assess physical conditions, observe employee behavior, and test environmental factors that could pose a risk to worker health.

Some hazards are immediately visible, while others require closer scrutiny, such as exposure to airborne contaminants or inadequate ventilation.

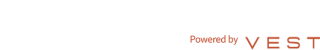

Spotting Hazards That Stand Out

Quick Tip: OSHA’s checklist is extensive. Ignoring small hazards can add up to serious violations.

Following Up on Employee Practices:

Quick Tip: Inspectors watch how workers interact with their environment–training means nothing if it’s not followed.

Detecting Environmental Factors

Quick Tip: What you can’t see, like toxic air exposure, can be just as dangerous as what’s in plain sight.

Asking for Proof of Compliance

Quick Tip: Even if a workplace looks safe, missing paperwork can lead to citations.

Fixing Hazards on the Spot

Quick Tip: Immediate corrections will be explored further in the next section–what happens next determines whether violations escalate.

III. Employee Interviews

During an OSHA audit, paperwork and policies tell one side of the story—but employees tell the rest. Interviews give inspectors a firsthand look at how safety measures function in reality, offering insight that written records often miss.

Whether it’s proper PPE usage, emergency preparedness, or knowledge of workplace hazards, these discussions help determine whether safety protocols are truly followed or just exist on paper. To learn more, ask yourself these questions:

Why OSHA interviews employees during an audit?

A company may have a well-documented safety program, but if employees aren’t aware of the procedures—or don’t follow them—there’s a problem.

Interviews allow OSHA inspectors to gauge the effectiveness of workplace training, ensuring workers understand safety regulations and their rights. These conversations also provide insight into potential hazards that leadership may have overlooked or ignored.

Through direct discussions, inspectors learn whether workers feel safe, if they know how to report hazards, and if they have the proper protective equipment for their job.

A well-trained workforce strengthens a company’s compliance record, while widespread confusion or uncertainty can indicate deeper safety issues.

How would they encourage employers for some feedback?

Employees may hesitate to speak up if they fear backlash from management. That’s why OSHA ensures that all interviews remain confidential, protecting workers from retaliation.

Inspectors may speak with employees privately to encourage honest answers, assuring them that their responses will not be shared with their employer in a way that identifies them.

Workplace culture plays a role in how open employees are during interviews. If workers fear consequences for speaking the truth, it raises a red flag for OSHA.

An environment where safety concerns go unreported or, worse, are dismissed can lead to severe penalties.

What Kind of Questions Do OSHA Inspectors Ask?

Interview topics depend on the industry and nature of the inspection, but some key areas are consistent across workplaces. Employees may be asked:

- Do you know what to do in an emergency?

- Have you received training on the proper use of PPE?

- Are there any safety hazards in your work area that concern you?

- Do you feel comfortable reporting unsafe conditions?

- Have you ever witnessed a safety rule being ignored?

What are the employees’ rights and their role in compliance?

Workers are not obligated to answer OSHA’s questions, but they do have the right to share concerns without fear of retaliation. Employers cannot intimidate, threaten, or discipline employees for participating in an audit interview.

In cases where a company has a history of discouraging safety complaints, OSHA may take a closer look at whistleblower protections and whether legal violations have occurred.

A company’s strongest asset in an audit is a workforce that understands and follows safety procedures.

When employees are well-trained, aware of their rights, and confident in their workplace’s commitment to safety, it strengthens the company’s compliance standing.

How Employee Interviews Impact Audit Findings?

What employees say–or don’t say–can heavily influence the outcome of an OSHA audit. Inspectors will dig deeper if interviews reveal inconsistencies between what’s documented and what’s happening on the floor.

For example, if training logs claim all employees have been fit-tested for respirators but multiple workers admit they’ve never received a test, that raises immediate concerns.

Likewise, if employees are unclear about evacuation procedures or don’t know where to find first aid stations, it suggests that training is either inadequate or nonexistent.

A workplace where employees confidently answer safety questions is a sign of strong compliance.

However, hesitation, uncertainty, or outright contradictions between workers and management may signal deeper problems that could lead to citations or corrective actions.

IV. Sampling and Testing

Not all workplace hazards are immediately visible. OSHA inspectors use sampling and testing to measure air quality, noise levels, ventilation efficiency, and other factors that impact worker safety.

These tests help determine whether a workplace meets regulatory safety standards or if employees are being exposed to harmful conditions.

The table below outlines the eight key sampling types used during OSHA audits:

| Sampling Type | Sampling Methods | Analysis and Results | Documentation |

|---|---|---|---|

| Air Quality Testing | Inspectors collect air samples using pumps and filters to detect contaminants like dust, fumes, and toxic chemicals. | Test results are compared to OSHA’s Permissible Exposure Limits (PELs) to determine if air quality meets safety standards. | Employers must keep air quality test reports for future reference and regulatory compliance. |

| Noise Level Monitoring | Sound meters and dosimeters measure decibel levels in different work areas to assess prolonged noise exposure. | Results indicate whether workers need hearing protection or if noise reduction measures are required. | Noise exposure records must be maintained, especially for employees working in high-decibel environments. |

| Ventilation Assessment | Inspectors check airflow systems, fume hoods, and exhaust fans to ensure hazardous substances are being properly filtered. | Data reveals if ventilation is adequate or if improvements are needed to prevent chemical buildup. | Employers should document ventilation maintenance schedules and airflow measurements. |

| Surface Contamination Sampling | Wipes and swabs are used to test work surfaces for hazardous residues, such as lead, asbestos, or chemical dust. | Results determine if decontamination procedures are effective or if additional cleaning protocols are necessary. | Records must confirm routine surface testing, especially in industries handling toxic substances. |

| Water Quality Testing | Inspectors collect water samples to check for contaminants, such as heavy metals, bacteria, or chemical pollutants. | Test results determine if water sources meet OSHA’s safety and sanitation standards. | Water testing records should be maintained to prove compliance with occupational hygiene regulations. |

| Heat Stress Monitoring | OSHA measures temperature, humidity, and worker hydration levels in high-heat environments using heat index calculations. | Data helps determine if workers are at risk for heat stress, requiring better cooling measures or hydration protocols. | Employers must document heat exposure prevention efforts, including breaks and access to water. |

| Radiation Exposure Assessment | Inspectors use radiation detectors to measure exposure levels in workplaces handling X-rays, lasers, or radioactive materials. | Readings confirm whether radiation shielding and safety protocols are adequate to protect employees. | Radiation exposure logs must be maintained, and workers must be provided with proper protective equipment. |

| Chemical Exposure Sampling | OSHA collects air, surface, or bodily fluid samples to detect harmful chemical exposure in workers. | Results show that if employees are being overexposed to hazardous substances, stronger safety measures are required. | Employers must maintain chemical exposure records and ensure proper training for handling toxic materials. |

If any test results exceed OSHA’s safety thresholds, employers must take corrective action–this may involve improving ventilation, supplying enhanced PPE, implementing stricter decontamination procedures, or reducing exposure levels.

Maintaining accurate documentation ensures compliance and helps businesses track improvements over time.

V. Immediate Corrections

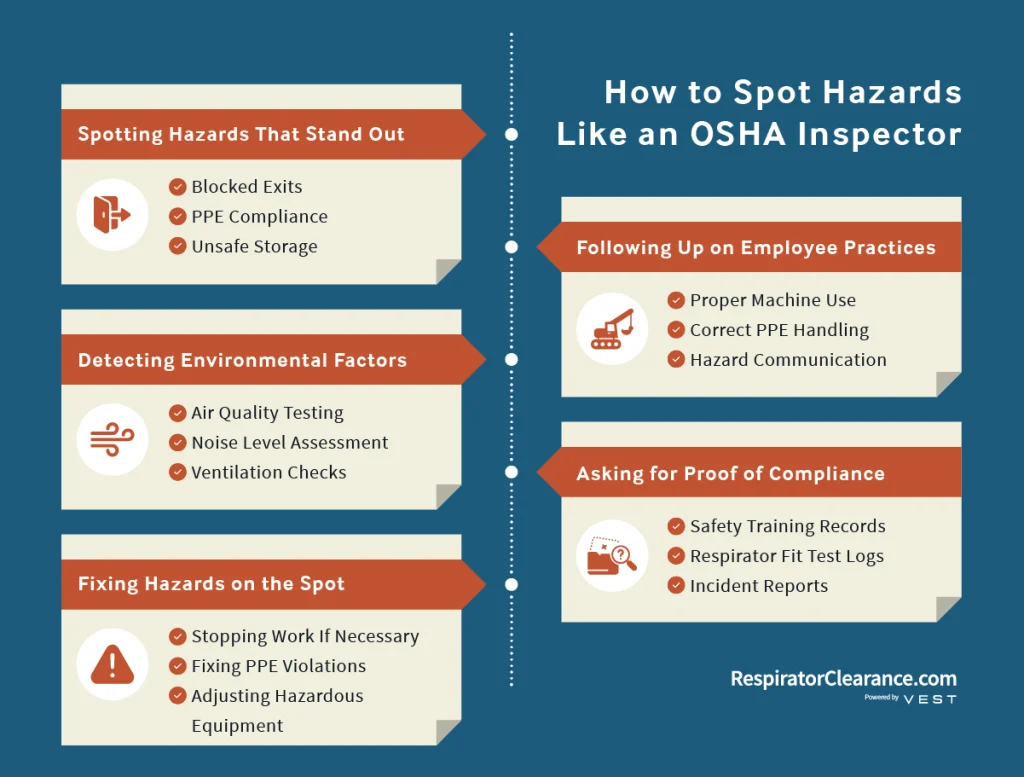

When OSHA inspectors uncover an immediate danger, businesses don’t have the luxury of waiting–action must be taken on the spot. Whether it’s a malfunctioning ventilation system, an unprotected worker handling hazardous materials, or blocked emergency exits, these violations demand urgent attention.

The following steps outline how immediate corrections are handled during an OSHA walkthrough.

Step 1: Identifying Imminent Dangers

Not all hazards require instant correction, but imminent dangers do. OSHA defines these as situations that could cause death or serious injury before the issue can be addressed through normal procedures. Inspectors look for risks such as:

- Exposed live electrical wires near workstations

- Respiratory hazards due to lack of ventilation or improper PPE

- Unsecured machinery or missing lockout/tagout procedures

- Toxic chemical leaks or improper storage of flammable substances

If an immediate threat to worker safety is found, OSHA may issue a stop-work order–halting operations in affected areas until the issue is resolved.

Step 2: Employer’s Responsibility to Fix the Issue

Once a hazard is identified, the employer is legally required to take corrective action right away. This could mean:

- Shutting down dangerous equipment until repairs are made

- Providing workers with proper PPE if respiratory protection is inadequate

- Clearing emergency exits and ensuring pathways remain unobstructed

- Evacuating employees from hazardous areas if exposure risks are high

Quick decision-making is key, delaying corrective action puts employees at risk and can result in severe OSHA penalties.

Step 3: Documenting Corrective Actions

Fixing a problem isn’t enough–it must be recorded. Employers need to document:

- The identified hazard and the immediate steps taken to resolve it

- Date and time of correction

- Any equipment repairs, PPE replacements, or safety training conducted

Thorough documentation helps prove compliance if OSHA follows up later. It also prevents repeat violations by ensuring proper corrective measures were implemented.

Step 4: OSHA Follow-Up Inspection

Once an immediate correction is made, the process isn’t over. OSHA may return for a follow-up inspection to verify that:

- The hazard has been fully corrected

- Employees are following updated safety protocols

- No new risks have emerged as a result of the correction

If an employer fails to maintain the fix or tries to circumvent safety regulations, they could face steeper penalties.

The OSHA walkthrough isn’t just a formality but lies more on a critical step in ensuring workplace safety. From hazard identification to employee interviews and immediate corrections, every part of the process determines whether a business is genuinely compliant or simply hoping for the best.

Staying prepared means maintaining up-to-date documentation, training employees effectively, and addressing hazards before an inspection occurs.

Are You Audit-Ready for OSHA?

Don’t wait for a citation to take safety seriously. Respirator Clearance can help you assess risks, improve compliance, and confidently prepare for audits.

Contact us today to safeguard your workplace and meet OSHA standards.

For more information or a consultation, just visit our website.