Did you know that in 2016, a shipyard in Wisconsin faced almost $1.4 million in OSHA fines? They exposed workers to lead levels that were up to 20 times too high.

This fine shows why OSHA audit preparation is so important, especially for keeping respiratory safety programs compliant.

Preparation is not just about checking off tasks. It is about making a safe place for workers. This way, we ensure that we are ready for audits and that compliance is always a priority.

Making sure we have good respiratory protection programs and keeping records updated helps reduce risks. It also shows our commitment to safety.

Many businesses overlook small mistakes, like missing fit-test records or old safety logs. These can lead to expensive violations.

The good news? Avoiding these pitfalls is easier than you think.

By following OSHA regulations, conducting internal audits, and training employees, you can build a compliance strategy that always keeps your workplace inspection-ready.

Before the next surprise visit from OSHA, let’s go over the key steps to prepare. These steps will help you stay ready and avoid penalties.

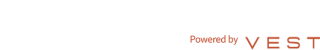

I. Understanding OSHA Standards

OSHA standards set the foundation for workplace safety. Failing to meet them can result in fines, legal trouble, and, most importantly, endanger employees.

To be ready for an audit, you need to know the rules. This includes respiratory protection, training needs, and record-keeping. Understanding these requirements helps you stay OSHA compliant.

Familiarizing with Relevant Standards

OSHA’s 29 CFR 1910.134 is the core regulation for respiratory protection, covering everything from fit testing to air quality standards.

It applies to any industry where workers may be exposed to airborne contaminants. However, the details differ by sector. For example, manufacturing plants have different rules than healthcare settings.

Employers can access official OSHA guidelines through the agency’s website, state labor departments, or professional safety organizations.

Interpreting these rules might seem overwhelming, but breaking them down into industry-specific checklists makes compliance much easier.

Regular Training & Updates

Workplace safety isn’t a one-time lesson. OSHA (Occupational Safety and Health Administration) requires ongoing training to ensure employees stay informed about new hazards, equipment updates, and compliance changes.

While general OSHA training should be conducted annually, industries with high exposure risks may need more frequent refresher courses.

The best way to stay compliant is to use OSHA-approved resources. These include certification programs, online courses, and safety drills sponsored by employers.

Keeping training engaging—through interactive sessions or hands-on demonstrations—also improves retention and helps prevent safety violations.

Documentation & Record-Keeping

Proper documentation is what separates compliant businesses from those facing violations. OSHA requires employers to keep detailed records of fit tests, hazard assessments, and employee training logs.

Whether you use digital systems or traditional paperwork, you must update records and keep them readily available for inspectors.

Companies that fail to maintain proper documentation risk fines, even if their workplace is otherwise safe. Avoid this mistake by setting up a structured filing system and regularly reviewing records for accuracy.

II. Conducting Internal Audits

Internal audits identify safety gaps before OSHA inspectors do. A well-planned audit process can prevent violations, improve workplace conditions, and reinforce a strong safety culture.

By doing regular inspections, checking for hazards, and involving employees, businesses can prevent problems and avoid expensive fines.

Regular Inspections: Spotting Issues Before They Become Violations

Routine internal safety audits help identify potential hazards before injuries or compliance violations occur. OSHA recommends conducting quarterly audits for high-risk industries and at least annual audits for lower-risk environments.

The key is consistency—regular inspections make it easier to track trends and spot recurring issues.

Some of the most common red flags include:

(a) Blocked emergency exits

(b) Improperly stored hazardous materials

(c) Lack of respiratory protection enforcement

(d) Missing or outdated training records

One of the best ways to ensure compliance is by using an internal audit info sheet tailored to OSHA standards. This helps safety coordinators stay focused on key areas and provides clear documentation of findings.

Comprehensive Reviews: Evaluating Workplace Hazards

A thorough workplace hazard assessment form should cover everything from air quality tests to PPE (Personal Protective Equipment) effectiveness. Poor ventilation, improper respirator fit, and untested emergency equipment are all factors that could lead to OSHA citations.

To keep respiratory protection in check, companies should regularly inspect:

- Air monitoring systems – Ensuring contaminants stay below permissible limits.

- Ventilation and filtration systems – Verifying they’re functional and meet safety requirements.

- Respirator fit and condition – Ensuring masks are properly fitted and not damaged.

A hazard assessment form helps standardize this process and keeps workplaces aligned with OSHA regulations.

Documentation & Reporting: Keeping a Clear Paper Trail

Even the most thorough audits mean nothing if they aren’t properly documented. OSHA inspectors often ask for proof of compliance. Missing records can lead to fines, even if safety measures exist.

Key documents to maintain include:

- Inspection reports detailing findings and dates of audits.

- Corrective action plans showing how and when safety concerns were addressed.

- Maintenance logs for safety equipment like respirators and air filters.

Many businesses use digital record-keeping systems to streamline compliance tracking. Whatever method is used, documents should be easily accessible and regularly updated.

Employee Involvement: Encouraging a Speak-Up Culture

Employees are on the front lines of workplace safety and often notice issues before management does. Encouraging workers to report hazards can significantly improve safety conditions—as long as they feel comfortable doing so.

Ways to promote employee involvement:

- Anonymous safety surveys – Giving workers a risk-free way to report concerns.

- Open-door policy – Ensuring employees can discuss safety issues without fear of retaliation.

- Safety committees – Forming a dedicated team to oversee compliance efforts.

Workers who feel heard are more likely to take safety seriously and proactively prevent violations.

Continuous Improvement Strategies: Using Audits to Strengthen Safety

Internal audits shouldn’t just identify problems—they should lead to long-term improvements. Once an audit is complete, businesses should use the findings to refine policies and make lasting changes.

Steps to implement a strong safety culture:

- Analyze past audit results to identify trends and recurring violations.

- Update training programs to address the most common safety issues.

- Invest in better equipment if current solutions aren’t meeting compliance standards.

- Schedule follow-up audits to ensure corrective actions are effective.

Internal audits create a proactive safety environment where issues are caught and corrected long before an official inspection.

III. Maintaining Documentation

Missing paperwork is one of the easiest ways to get cited during an OSHA audit. Even if a workplace meets safety standards, failing to produce the right records can result in fines. Keeping documentation organized ensures compliance and makes inspections much smoother.

OSHA Documentation Checklist: What You Need Before an Audit

Every employer should have a set of core documents ready before an inspection. OSHA requires specific records to verify compliance with workplace safety and respiratory protection regulations. Some of the most important ones include:

- Respirator fit test records – Proof that employees have been properly tested for mask fit.

- Hazard assessments – Evaluations of workplace risks and the steps taken to reduce exposure.

- Training logs – Records of all OSHA-required safety training sessions.

- Medical evaluations – Clearance for employees required to wear respirators.

Having these documents on hand ensures businesses can quickly provide proof of compliance when asked.

Organizing Fit Tests, Hazard Assessments, and Training Logs

OSHA audits often involve spot-checking documentation, meaning inspectors will ask for specific records on the spot. Keeping files in a centralized location—whether physical or digital—prevents delays and confusion. Employers can:

- Store hard copies in clearly labeled binders.

- Use cloud-based systems for easy access.

- Assign a compliance officer to oversee documentation updates.

Regular audits of record-keeping practices help ensure all documents are current and meet OSHA standards.

Best Tools for Compliance Management

Manual tracking can be overwhelming, which is why many companies turn to digital compliance tools. Software like EHS management systems or OSHA-certified platforms help:

- Automate training reminders.

- Generate audit-ready reports.

- Securely store compliance records.

Digital tools reduce human error and make it easier to keep up with changing regulations.

IV. Employee Training & Readiness

Training is not only limited to OSHA requirements but also about making sure every worker understands the risks and how to protect themselves.

Without proper training on respiratory safety and workplace dangers, even the best equipment can’t stop accidents.

A good training program helps employees meet compliance standards. It also teaches them the skills to respond well in high-risk situations.

Comprehensive Training Programs: What OSHA Requires vs. What’s Recommended

OSHA mandates baseline safety training for all employees, but some industries require more than the standard courses.

For example, workers exposed to hazardous airborne contaminants must be trained under 29 CFR 1910.134, which covers respirator use, fit testing, and medical evaluations.

However, many businesses go beyond the minimum requirements by implementing additional training, such as:

- Advanced hazard recognition – Helping employees spot risks before they become serious.

- Emergency response training – Preparing workers to handle chemical spills or toxic exposures.

- Industry-specific courses – Tailoring safety education to job-specific risks, such as confined space entry or silica dust exposure.

Regular Training Sessions: How Often Is Enough?

OSHA requires safety training to be ongoing, but how often should refresher courses be held? Annual training is the general rule, but some industries require more frequent sessions. For example,

(a) Respirator fit testing must be conducted at least once a year, while

(b) Some hazardous materials training may need updates every six months.

When it comes to training formats, employers have two main options:

- On-site training – This offers hands-on experience but requires scheduling flexibility.

- Online training – This is Convenient for busy teams but may lack practical application.

Many businesses discover that a hybrid approach works well. This method combines in-person training with online refreshers. It balances efficiency and effectiveness.

Hands-On Training: The Best Way to Learn Safety

Reading a manual on respirator use isn’t the same as wearing one in a real-world setting. Practical, hands-on training ensures employees know how to fit, wear, and maintain their safety gear properly. OSHA emphasizes the importance of:

- Fit-testing respirators to ensure they provide an airtight seal.

- Demonstrating PPE use so workers understand its limitations.

- Running emergency drills to prepare for worst-case scenarios.

Employees who get hands-on experience retain information better and are more likely to apply it in critical moments.

Training Documentation & Record-Keeping: Proof of Compliance

Even the most well-trained workforce can run into compliance issues if records aren’t kept properly. OSHA requires employers to maintain:

- Training logs with course names, dates, and employee participation.

- Fit test records to confirm workers can safely use respirators.

- Sign-off/in sheets proving employees understood the training.

Employee Involvement & Feedback: Making Training Matter

Training is only effective if employees take it seriously. Encouraging workers to participate in safety discussions and provide feedback on training sessions can improve engagement and retention. Simple strategies include:

- Post-training quizzes to reinforce key takeaways.

- Feedback forms to measure training effectiveness.

- Employee-led safety talks where workers share their experiences.

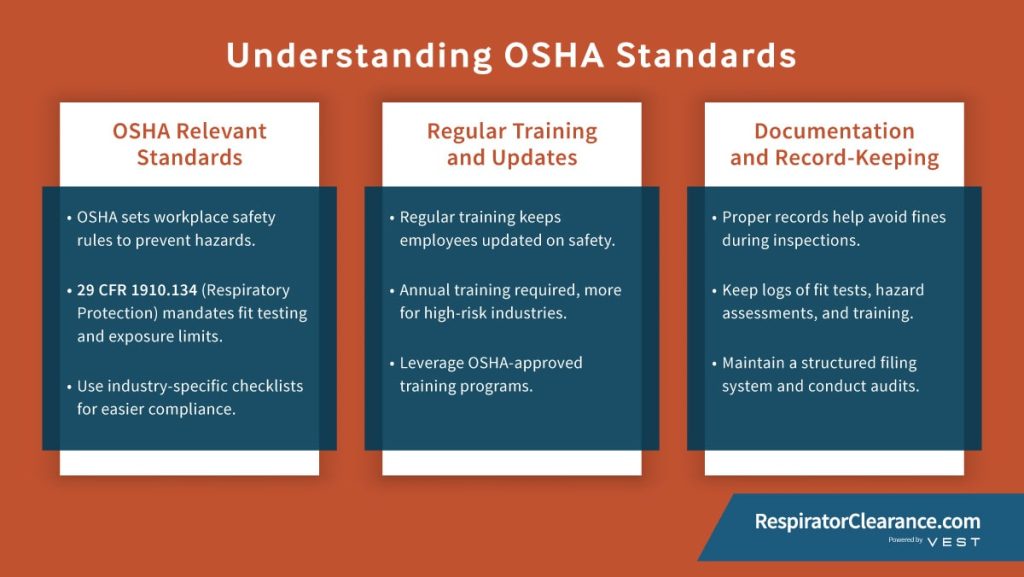

V. Designating a Safety Coordinator

A well-trained workforce is important. However, even the best training programs need someone to oversee workplace safety.

The safety coordinator plays an indispensable role in maintaining OSHA compliance, handling inspections, and ensuring that respiratory protection programs are followed correctly.

Selecting the right person for this position allows businesses to create a workplace that stays audit-ready and safe for employees.

Role & Responsibilities: The Backbone of Workplace Safety

A safety coordinator lies more than its title. It’s an integral function in OSHA compliance. This individual is responsible for:

- Overseeing respiratory protection programs – Ensuring all employees using respirators are fit-tested and medically evaluated.

- Maintaining compliance – Regularly reviewing workplace policies to align with OSHA regulations.

- Serving as the point-of-contact during inspections – Accompanying auditors, answering compliance questions, and providing necessary documentation.

Knowledge & Expertise: What Makes a Good Safety Coordinator?

Not everyone is suited for this role! A strong safety coordinator needs a combination of experience, knowledge, and up-to-date training. While OSHA doesn’t require a specific degree for this position, many employers prefer candidates with:

- Certifications like OSHA 30-Hour Training or Certified Safety Professional (CSP).

- Industry-specific knowledge, especially in high-risk sectors like construction or manufacturing.

Since OSHA rules often change, safety coordinators need to stay updated. They can do this by reading newsletters, attending workshops, and taking refresher courses. This helps keep policies current.

Training & Communication: Keeping Everyone on the Same Page

The best safety coordinators aren’t just knowledgeable. They also know how to communicate effectively. Safety meetings, toolkit talks, and training refreshers help employees stay updated on new risks and OSHA requirements.

Keyways to improve workplace safety communication include:

- Conducting monthly safety briefings to review best practices and recent updates.

- Encouraging open conversations between workers and management about safety concerns.

- Using visual aids and signage to reinforce key compliance points.

- When employees understand the why behind safety policies, they’re more likely to follow them.

Record-Keeping & Reporting: Documenting Safety for Compliance

An OSHA audit can happen at any time; without the proper records, even a compliant workplace can face penalties. A safety coordinator must ensure that all safety-related data is accurately tracked and easily accessible.

Essential records include:

- Incident reports – Logging workplace accidents, near-misses, and corrective actions.

- Audit findings – Keeping records of past inspections and compliance adjustments.

- Employee safety records – Document fit tests, medical evaluations, and completion of training.

VI. Knowing Your Rights as an Employer

When an OSHA inspector arrives at your workplace, you are not required to allow access or comply without question immediately. Employers have specific rights that protect them during an inspection, ensuring the process remains fair and follows proper procedures. Knowing these rights helps you stay in control while maintaining compliance.

Below is a structured table outlining your inspection rights, what they mean, and the steps to take if those rights are not respected.

| Employer Right | What It Means | Steps to Take if Not Respected |

|---|---|---|

| Right to Request Credentials | You can ask for an inspector’s official OSHA ID before granting access. OSHA compliance officers must provide proper identification. | Do not allow entry until verification is complete. Contact the local OSHA office if the inspector refuses to provide ID. |

| Right to Know the Reason for Inspection | Employers have the right to understand why their workplace was selected for an audit—whether it’s a routine check, a complaint, or a recent incident. | Ask the inspector for a written explanation of the reason for the inspection. If based on a complaint, request a copy of the complaint details (without employee names). |

| Right to Accompany the Inspector | A designated representative, such as a safety coordinator or legal counsel, can be present throughout the inspection to observe and take notes. | If an inspector refuses to allow an employer representative, document the refusal and contact OSHA to report the issue. |

| Right to Refuse Entry Without a Warrant | OSHA cannot force entry unless they have a warrant. Employers can legally request that the inspector return with one. | Politely inform the inspector that a warrant is required for entry. Be aware that refusal may increase scrutiny on future inspections. |

| Right to a Closing Conference | Employers are entitled to a final discussion with the inspector to review findings, potential citations, and next steps. | If an inspector leaves without providing a summary of findings, follow up with OSHA to request official documentation. |

Thorough OSHA audit preparation not only helps avoid costly violations but also creates a safer, more compliant workplace. By keeping records up to date, training employees, and conducting internal audits, businesses can stay ahead of potential issues.

When the time comes for an OSHA inspection, a well-prepared team and a solid final checklist can turn a stressful inspection process into a smooth, successful outcome.

Don’t Risk Violations – Start Your OSHA Audit Preparation Now!

Ensure your business is always audit-ready with Respirator Clearance’s easy-to-use compliance tools and expert support. Our tailored safety solutions keep your workplace protected and up to standard.

Don’t wait—take action today!

Visit Respirator Clearance for more information or to schedule a consultation.